-

What is the Operating Voltage of a Battery?

Also known as terminal voltage, refers to the potential difference between the positive and negative terminals of the battery in the working state ( there is current through the circuit ) . In the battery discharge working state, when the current flowing through the battery, do not need to overcome the resistance caused by the internal resistance of the battery, so the working voltage is always lower than the open circuit battery, charging is the opposite. Li-ion's discharge working voltage is about 3.6V.

-

Resistance and Conductivity in Electric Batteries: A Simplified Explanation

The concepts of resistance and conductivity are essential in the field of electricity and have a significant relationship. Resistance is the measure of a material's opposition to the flow of electric current in an electric field, denoted by the Greek letter ρ (rho) and measured in ohm-meters (Ω·m). Let's explore the basics of resistance and conductivity, including their units and relationship.

Resistance

1. What is resistance?

Resistance is a physical property of a material that quantifies its hindrance to the flow of electric current. It is typically represented by the symbol ρ (rho) and measured in ohm-meters (Ω·m).

2. What is the unit of resistance?

The unit of resistance is ohm-meters (Ω·m) or ohms per square millimeter per meter (Ω·mm²/m).

3. How is resistance calculated?

Resistance can be calculated using the formula ρ = R · S / L, details:

- ρ is the resistance, measured in ohm-centimeters (Ω·cm).

- R is the resistance value, measured in ohms.

- S is the cross-sectional area, measured in square centimeters.

- L is the length of the conductor, measured in centimeters.

Conductivity

4. What is conductivity?

Conductivity, also known as electrical conductivity, is a physical property that describes the ease with which electric charge flows through a material. It is denoted by the symbol σ (sigma) and is measured in siemens per meter (S/m).

5. How are resistance and conductivity related?

Resistance (ρ) and conductivity (σ) are reciprocals of each other. Conductivity measures the ability of a material to conduct electric current, while resistance measures the hindrance to the flow of electric current. The relationship between them can be expressed as:

σ = 1 / ρ

where σ represents conductivity and ρ represents resistance.

In practical terms, materials with high conductivity have low resistance, and vice versa. For example, conductive materials like copper and silver have high conductivity and low resistance, allowing electric current to flow with minimal hindrance. On the other hand, insulating materials like rubber and plastic have low conductivity and high resistance, impeding the flow of electric current.

Understanding resistance and conductivity is crucial in circuit design and electronic engineering. By controlling the conductivity and resistance of materials, it becomes possible to regulate electric current, optimize circuit performance, and manage power consumption.

-

What Does DIN RAIL DC UPS Mean and the Battery Power?

What Is DIN RAIL?

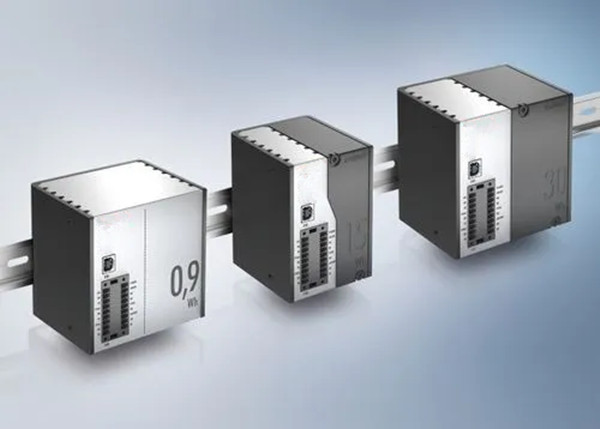

DIN RAIL is a universal mounting bracket widely used in the installation and maintenance of various industrial and electronic equipment. DIN RAIL is typically a standardized metal rail with dimensions, shapes, and mounting hole distances that comply with the German Industrial Standard (DIN), hence the name DIN RAIL.

DIN RAIL is commonly used for installing and securing electrical, electronic, and automation equipment such as controllers, relays, PLCs, and power supplies. It can be fixed in cabinets, electrical enclosures, control panels, and other equipment by using mounting holes and slots, providing a stable support and installation environment. DIN RAIL can also be customized in different lengths, materials, and shapes to meet the installation requirements of different equipment.

DIN RAIL offers advantages such as simple structure, convenient installation, and reliable safety, making it widely used as a mounting bracket in industrial and electronic equipment. Besides the DIN standard, there are also other standards and forms of rails used in specific application areas, such as the National Electrical Manufacturers Association (NEMA) standard in the United States and the British Standard (BS) in the UK.What Does DIN RAIL DC UPS Mean?

DIN RAIL DC UPS stands for DIN Rail Direct-Current Uninterruptible Power Supply. It is a device used for direct current (DC) power systems, designed to provide backup power in the event of a power outage.

DIN Rail refers to a standardized metal rail typically installed in electrical equipment control cabinets or distribution boxes. DIN RAIL DC UPS is designed to be installed on this standard rail, facilitating integration into the electrical control system.

DIN RAIL DC UPS and Its Power Supply(Pic: Internet)

DIN RAIL DC UPS typically consists of one or multiple batteries, which convert external DC power sources (such as the power grid or other DC power sources) into stable DC power suitable for equipment through rectifiers. When the external power source fails or is interrupted, the battery pack automatically provides power, ensuring uninterrupted power supply to the equipment, preventing data loss or system failures. Therefore, the battery backup for DIN RAIL DC UPS is necessary. And Knowing more about the batteries is helpful for our decision.

What Batteries Are Good For DIN RAIL DC UPS?

For DIN RAIL DC UPS, the choice of a suitable battery type depends on specific application requirements and budget considerations. Here are several common battery types:

1.Lithium iron phosphate (Short for LiFePO4/LiFe/LFP) batteries (One of Li-ion Batteries)

Lithium-ion batteries offer high energy density and low self-discharge rates. They are recognized as environmentally friendly batteries, with minimal environmental impact. LiFePO4 is the safest type in LIBs. Additionally, they are lighter, have longer lifespans, higher cycle counts, and require no regular maintenance compared to lead-acid batteries. However, they tend to be relatively more expensive.

2.Nickel-Metal Hydride Batteries

Nickel-metal hydride batteries are an environmentally friendly alternative to nickel-cadmium batteries, without the environmental concerns associated with cadmium. They have higher cycle life and lower self-discharge rates, but their energy density is relatively lower. Under the same power output, lithium iron phosphate batteries would have smaller volume and weight compared to nickel-metal hydride batteries.

3.Nickel-Cadmium Batteries

Nickel-cadmium batteries are a reliable backup power option with good cycle life and high temperature tolerance. They are relatively heavier and contain the environmentally hazardous substance, cadmium. Therefore, the use of nickel-cadmium batteries may require compliance with specific environmental regulations.

4.Lead Acid Batteries

Lead acid batteries are a cost-effective and mature choice, providing reliable backup power support. They have high energy density and can deliver high current in a short period. However, they are relatively heavier and require regular maintenance.

When selecting the appropriate battery type, factors such as capacity requirements, system weight limitations, battery lifespan, environmental considerations, cost, and safety requirements should be taken into account. The best choice will depend on your specific application and prioritized factors.

Why Use LiFePO4 Batteries for DIN RAIL DC UPS?

Compared to lead-acid batteries, there are several advantages and disadvantages of using lithium iron phosphate (LiFePO4) batteries for DIN RAIL DC UPS:

1. Advantages of Using LiFePO4 Batteries for DIN RAIL DC UPS:

●Long lifespan:

Over 2000 cycles, LiFePO4 batteries' significantly longer than lead-acid batteries, resulting in a longer overall lifespan.

●Smaller size and lighter weight:

Higher energy density, allowing LiFePO4 batteries for smaller battery sizes and reduced weight. This helps in saving equipment space and transportation costs.

●Higher energy density:

Compared to lead-acid batteries, LiFePO4 higher energy density providing longer backup times while occupying a smaller volume.

●Shorter charging time:

LiFePO4 batteries have a faster charging speed than lead-acid batteries, allowing for quicker recharging and restoration of backup capabilities.

●Eco-Friendly:

Lithium FePO4 batteries and packaging do not contain any heavy metals such as lead, mercury, etc. The production and use process is non-toxic and non-polluting, ensuring human and ecological safety.

●Wide temperature range:

LiFePO4 batteries have a wider operating temperature range compared to lead-acid batteries, enabling them to perform well in various temperature conditions.

Considering these advantages, LiFePO4 batteries are often preferred for DIN RAIL DC UPS due to their longer lifespan, smaller size, lighter weight, higher energy density, faster charging time, environmental friendly, and wider temperature range.

2. Drawbacks of DIN RAIL DC UPS Using LiFe Batteries:

●Higher primary purchase cost

The relatively high cost of LFP batteries may increase the procurement cost of equipment, but can reduce the price of DC UPS maintenance costs throughout the life cycle of use.

●Charging voltage and current limitations

Charging lithium iron phosphate batteries requires careful control of voltage and current to avoid overcharging and over-discharging, requiring stricter management and control.

The above information explains what batteries are used for DIN RAIL DC UPS. From the given details, it can be observed that the use of lithium iron phosphate batteries as backup power for DIN RAIL UPS is becoming a future trend. With the continuous development and maturation of LFP battery technology, these batteries offer numerous advantages such as long cycle life, high energy density, high safety, wide temperature range, and environmental friendliness. They are well-suited to meet the diverse needs of DIN RAIL UPS in various application scenarios.

-

Frequently Asked Questions for UPS Battery Replacement

Uninterruptible Power Supply (UPS) systems are a crucial component in safeguarding electronic devices and data against power disruptions. However, over time, the batteries in UPS units may require replacement. This article addresses some common questions regarding UPS battery replacement.

Is it worth replacing batteries in UPS?

In fact, it depends. The batteries are the lifeline of the UPS, providing power during electrical outages or fluctuations. By replacing the batteries, you ensure that your UPS continues to function effectively, protecting your connected equipment and preventing data loss. Replace UPS batteries is more cost-effective than buying a new one. But if your UPS has become flaky in some fashion, or it doesn't have the features that you want. Then you should buy a new UPS.

How do I know if my UPS battery needs replacing?

The battery in a UPS is a crucial component, and over time, it may degrade and require replacement. Here are some signs that indicate your UPS battery might need replacing:

◆Audible Alarms: UPS units often emit a beeping sound to alert users when the battery is low or needs replacement.

◆Reduced Runtime: If your UPS provides significantly less backup time than before, it's a sign that the battery capacity has diminished.

◆Visual Indicators: Some UPS models have LED indicators that change color or flash to indicate battery health. Refer to your UPS manual for specific information.

◆Age: VRLA UPS batteries typically have a lifespan of 3-5 years. If your UPS is older than that, consider replacing the batteries preemptively.

What is the life expectancy of a UPS battery?

The life expectancy of UPS batteries can vary based on the type of battery chemistry used. Although alternatives such as lithium-ion battery are becoming more popular and commercially viable, the majority of UPS today still use traditional sealed lead-acid (SLA) batteries. SLA batteries typically have a life expectancy of 3 to 5 years. SLA batteries are often more cost-effective than lithium-ion batteries, making them a common choice for UPS applications. Lithium-ion batteries generally have a longer life expectancy compared to SLA batteries. They can last 5 to 10 years or more, depending on usage and environmental conditions. Lithium-ion batteries offer a higher energy density, meaning they can provide more power in a smaller and lighter package.

Why do UPS batteries fail so quickly?

UPS batteries can fail prematurely for a variety of reasons. Understanding these factors can help users take appropriate measures to maximize the lifespan of UPS batteries. Here are some common reasons why UPS batteries might fail quickly:

◆Temperature: High temperatures can accelerate chemical reactions within the battery, leading to a shorter lifespan.

◆Overcharging/Undercharging: Improper charging can cause stress on the battery, leading to premature failure.

◆Old Age: As batteries age, their ability to hold a charge diminishes.

◆Manufacturing Quality: Lower quality batteries may have a shorter lifespan than high-quality ones.

How often do you need to replace UPS battery?

The frequency of UPS battery replacement depends on factors like usage, environmental conditions, and battery quality. On average, replacement every 3 to 5 years is recommended. Regularly monitoring battery health and addressing warning signs can help in timely replacements.

How much does it cost for UPS battery replacement?

The cost of UPS battery replacement varies depending on factors like the UPS model, battery capacity, and brand. As a rough estimate, replacement batteries can range from $50 to $200 or more. It's recommended to check with the UPS manufacturer or authorized dealers for specific replacement batteries compatible with your UPS model. Additionally, consider whether you'll be replacing the battery yourself or hiring a professional, as installation costs can also contribute to the overall expense. When replacing UPS batteries, it's important to choose batteries that meet the specifications of your UPS, adhere to safety guidelines, and follow the manufacturer's recommendations.

What is the procedure for UPS battery replacement?

The procedure for UPS battery replacement can vary among different models. However, a general guideline includes:

Turn off and unplug the UPS: Ensure the UPS is powered down and disconnected from the electrical source.

◆Access the battery compartment: Open the UPS and locate the battery compartment.

◆Remove old batteries: Disconnect the old batteries, following the manufacturer's instructions. Handle batteries carefully and dispose of them according to local regulations.

◆Install new batteries: Insert the new batteries, making sure to connect them correctly.

◆Close the battery compartment: Securely close the UPS cover.

◆Power up the UPS: Plug in the UPS and turn it on. Monitor for any warning lights or alarms.

Always refer to the specific UPS manual for detailed instructions on battery replacement to ensure a safe and effective procedure.

Conclusion

In conclusion, understanding the importance of UPS battery replacement and being aware of the signs and procedures can help users maintain the reliability of their UPS systems and safeguard their valuable electronics. Regular monitoring and timely replacement contribute to the overall effectiveness of the UPS in providing uninterrupted power protection. As a global leader in lithium battery cell manufacturing, Grepow offers professional customization solutions for 12V and 24V UPS battery and Battery Management Systems (BMS), catering to your specific application requirements. If you have any questions or needs, please feel free to contact us at info@grepow.com.

Related Articles:

-

12V UPS Battery FAQs

Uninterruptible Power Supply (UPS) systems play a crucial role in safeguarding electronic devices from unexpected power interruptions. The heart of a UPS system is its battery, and one of the most commonly used battery voltages is 12V. In this article, we'll explore frequently asked questions about 12V UPS battery to help users better understand their functionality and maintenance.

Why is a 12V battery usually used in UPS?

A 12V battery is a popular choice for UPS systems due to its versatility and compatibility. Many electronic devices and systems are designed to operate with 12V DC power, making these batteries a suitable and widely available option for UPS applications. Despite the availability of 24V and 48V batteries, opting for them can result in severe damage to the house and pose risks to loved ones. Hence, the industry standard has remained unchanged for years, with the 12V UPS battery being the preferred choice for its ease of management and installation in conjunction with the inverter. In smaller UPS systems, a commonly used battery is the 12V 7Ah, capable of powering devices such as routers, modems, surveillance cameras, and small electronic gadgets during power outages.

12V UPS battery: Lead-Acid vs lithium

Choosing between lead-acid and lithium-ion 12V UPS battery involves trade-offs. Lead-acid batteries are heavier, bulkier, and have a shorter lifespan but come with a lower initial cost. On the other hand, lithium-ion batteries offer higher energy density, making them more compact and lightweight. They have a longer lifespan, faster charging times, but come with a higher upfront cost. Consider factors such as space, weight constraints, lifespan requirements, and budget considerations to make an informed decision based on your specific needs and preferences.

In general, you can replace 12V UPS lead-acid batteries with 12V UPS lithium battery. However, while replacing lead-acid batteries with lithium batteries can offer benefits such as longer lifespan and higher energy density, it's crucial to follow manufacturer guidelines and ensure compatibility to prevent damage to the UPS system or safety issues. Always prioritize safety and adhere to recommended practices throughout the replacement process.

How many hours will a 12V 7Ah battery last?

The runtime of a 12V 7Ah battery depends on the power consumption of the connected devices and the efficiency of the UPS system. As a general guideline, a 7Ah battery can provide power for approximately 30 minutes to an hour, depending on the load. The method for calculating the power supply time of UPS with different battery capacities is as follows:

1. Determine the UPS Load:

Identify the power consumption (in watts) of the devices connected to the UPS. This information is usually provided on the devices or in their user manuals.

2. Convert Load to Amps:

Calculate the load in amps by dividing the total power (in watts) by the UPS output voltage (typically 120V or 230V).

For example:

Load = 300 watts

Amps = 300W / 120V = 2.5A

3. Identify Battery Capacity:

Determine the ampere-hour (Ah) rating of the batteries. This information is usually marked on the batteries themselves.

4. Calculate Runtime:

Use the formula: Runtime (in hours) = Battery Capacity (Ah) / Load (Amps)

For example:

Battery Capacity = 10Ah

Runtime = 10Ah / 2.5A = 4 hours

5. Adjust for Efficiency:

Consider the efficiency of the UPS system. Multiply the calculated runtime by the UPS efficiency factor (usually expressed as a percentage).

For example:

If UPS efficiency is 90%, adjust runtime: 4 hours * 0.9 = 3.6 hours

Can I replace a 12V 7Ah battery with a 12V 12Ah battery?

The primary difference between a 7Ah and 12Ah UPS battery lies in their capacity to store electrical energy. A 12Ah battery has a higher capacity and can generally power devices for a more extended period during a power outage compared to a 7Ah battery. In many cases, you can replace a 12V 7Ah battery with a 12V 12Ah battery in a UPS system. Upgrading to a higher Ah (ampere-hour) rating increases the battery's capacity, providing longer backup power. However, it's crucial to ensure that the physical dimensions of the new battery fit within the UPS enclosure.

Conclusion

Understanding the basics of 12V UPS battery is essential for optimizing the performance and longevity of your uninterruptible power supply system. Whether you are considering a replacement or upgrading your current battery, being informed about these FAQs can help you make informed decisions to ensure reliable backup power for your electronic devices. As a global leader in lithium battery cell manufacturing, Grepow offers professional customization solutions for 12V and 24V UPS battery and Battery Management Systems (BMS), catering to your specific application requirements. If you have any questions or needs, please feel free to contact us at info@grepow.com.

Related Articles:

DC UPS vs AC UPS: What’s the Difference?

UPS Battery Market Forecast Research Report

Frequently Asked Questions for UPS Battery Replacement

-

Lipo Battery Storage FAQs

Lithium Polymer (LiPo) batteries have become increasingly popular in various applications, ranging from consumer electronics to RC hobbyist devices. Proper storage of LiPo batteries is crucial to ensure their longevity, safety, and optimal performance. In this article, we will address common FAQs regarding the LiPo battery storage, covering aspects such as duration, charging status, environmental conditions, and more.

How should LiPo batteries be stored?

LiPo batteries should be stored at a cool and dry place, away from direct sunlight and extreme temperatures. Ideally, a fireproof LiPo bag or metal container is recommended for storage to enhance safety.

How long can a LiPo battery sit unused?

LiPo batteries should not be left unused for extended periods. It is recommended to use or charge them at least every 3 months to prevent voltage drop and deterioration.

Is it better to store LiPo batteries charged or uncharged?

For long-term storage, LiPo batteries should be stored with a charge between 40-60%. Storing them fully charged or fully depleted for extended periods can lead to capacity loss and decreased performance.

How do you store LiPo batteries in the house?

Store LiPo batteries in a fire-resistant container, preferably a LiPo bag, and keep them in a cool, dry place. Avoid storing them near flammable materials or in direct sunlight.

Can I store LiPo batteries in the garage?

While it's possible to store LiPo batteries in the garage, it is crucial to ensure that the environment remains cool and dry. Avoid exposing them to extreme temperatures and protect them from potential fire hazards.

Can you store LiPos in cold weather?

Extreme cold can affect the performance of LiPo batteries. It is advisable to store them in a cool place, but not in freezing temperatures. Extreme cold can lead to reduced capacity and potential damage to the cells.

What's the best temperature for lipo battery storage?

The optimal temperature for storing LiPo batteries is in the range of 20°C to 25°C (68°F to 77°F). Storing LiPo batteries within this temperature range helps maintain their stability and longevity.

What is the best thing to store LiPo batteries in?

The best containers for LiPo bettery storage are fireproof bags or metal containers with tight-fitting lids. These provide an additional layer of safety in case of a battery failure.

What is the safe LiPo battery storage voltage?

The safe storage voltage for LiPo batteries is generally between 3.7V and 3.85V per cell. Storing them within this range helps maintain their health during periods of inactivity.

What is the storage voltage for 3.7V LiPo?

The storage voltage for a 3.7V LiPo cell is typically around 3.85V. Ensure that each cell in the battery is at this voltage range before storing.

What is the best percentage to store batteries?

Storing LiPo batteries at around 40-60% charge is considered optimal for long-term storage. This percentage helps prevent over-discharge and overcharge issues during extended periods of inactivity.

What voltage should a 3S LiPo be stored at?

A 3S (3-cell) LiPo battery should be stored at a total voltage of around 11.1V to 11.55V. This corresponds to approximately 3.7V to 3.85V per cell.

Conclusion

Proper storage is key to maximizing the lifespan and safety of LiPo batteries. Following these guidelines ensures that your batteries remain in optimal condition, whether used in consumer electronics, RC vehicles, or other applications. By understanding the best practices for LiPo battery storage, users can enjoy reliable performance and minimize the risk of safety hazards. As a global leader in lithium battery cell manufacturing, Grepow offers professional customization solutions for lipo battery and Battery Management Systems (BMS), catering to your specific application requirements. If you have any questions or needs, please feel free to contact us at info@grepow.com.

Related Articles:

Basis of LiPo Battery Specifications

Round LiPo Battery: A Comprehensive Guide

What Is an Ultra Thin LiPo Battery?

How to Choose Lipo Battery for Medical Device?

-

What is a smart ring battery and the manufacturing process?

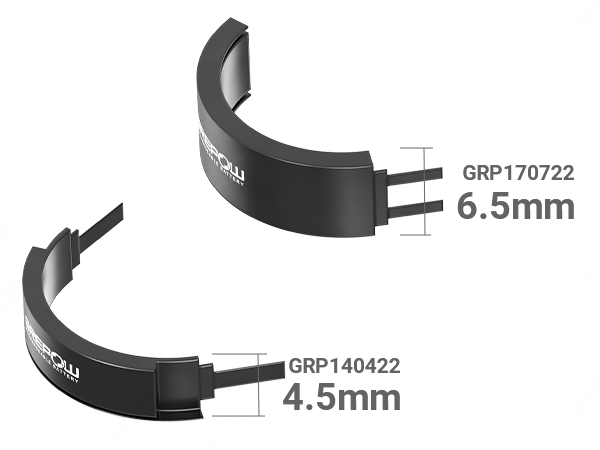

What is a smart ring battery?

A smart ring battery (mostly also known as curved lipo battery) is a small battery designed for smart rings, and they are an important part of wearable electronics. Smart ring batteries are usually made using lithium polymer battery technology because these batteries can be made in the desired shape and size to fit the compact design of the ring. Smart ring batteries are needed to provide smart rings with the necessary power to support the functions like health and exercise monitoring, notification alerts, gesture control, and navigation and location tracking.

What are the features of the smart ring battery?

1. High energy density: despite their small size, polymer lithium-ion batteries are able to provide high energy density, which means they can store more power in a relatively small space.

2. Lightweight and compact: the design of the battery must be coordinated with the overall internal and external structural design of the ring, so they need to be as lightweight and compact as possible.

3. Sufficient battery life: Smart rings usually require batteries to support a longer usage time to avoid frequent charging.

4. Safety: Since batteries are close to the user's skin, they need to meet strict safety standards to prevent overheating, short circuiting, or other potentially dangerous situations.

Which is better, smart ring battery stacking process or winding process?

Curved lipo battery as one of the important components of the smart ring, its performance quality can not only affect the service life and duration of the smart ring, but also affect the appearance of the smart ring size and aesthetics. Since this is the case, then the following Grepow will do a comparison of the current electronic smart ring battery process.

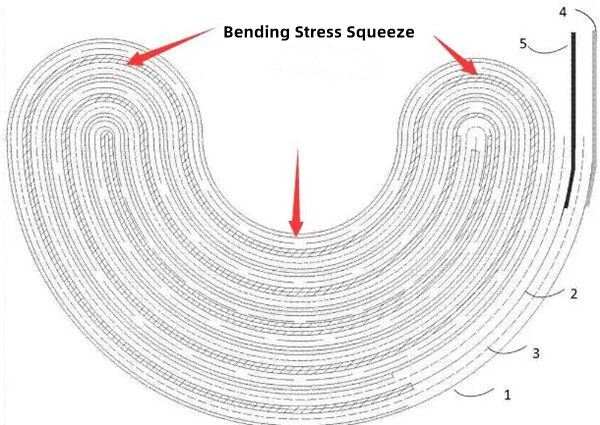

The smart ring batteries used now belong to the high energy density lithium batteries, and there are two main production processes: stacking and winding. Let's briefly explore the differences between these two processes of batteries together.

The ring battery made by stacking process can be more tightly sealed when the battery is molded into an arc, which will not affect the beauty of the battery edges and corners by edge wrinkles, and moreover, the battery pole coating will not be damaged due to severe extrusion, which will lead to capacity degradation, internal puncture short-circuiting, and shorter service life, and other consequences.

The ring battery made by stacked piece process, the piece-shaped battery pole piece is specially made for various shapes, when the battery is made into a curved mold, the sealing edge is more tight, the edge wrinkles are close to zero, and the corners of the battery are smooth; what's more important is that the battery will not be damaged due to the extrusion of the pole piece coating, and it will avoid the problems such as capacity degradation, short circuit of the internal puncture and short service life.

Ring batteries using the winding process, as shown above, not only have an unsightly appearance after the bending arc is formed, but the internal structure of the battery is likely to be damaged because of the extrusion caused by the bending. Even if the battery is used normally at first, but after a period of time, it is probable to be squeezed by the greater resistance of the place, resulting in easy heating or pole piece damage, the battery capacity will be greatly attenuated, the service life is also greatly shortened.

The above is a brief introduction to the "smart ring battery and production process comparison". When selecting ring batteries, manufacturers need to consider the battery life, charge/discharge cycle stability, battery production process and compatibility with other ring components. In addition, in order to meet the needs of different markets, battery suppliers need to offer a diverse range of products to suit different designs and technical specifications.

Related Articles:

The NeoRRow Series Curved Lithium Polymer Batteries: Coming Soon!

Key Considerations for Custom Curved Batteries You Should Know

Curved Lithium Polymer Battery - Wearable Device Mobile Power

How to custom your special-shape battery-Curved LiPo

-

5 Inch FPV Drone FAQs

If you're new to the world of FPV (First Person View) drones or a seasoned pilot looking to expand your knowledge, understanding the ins and outs of 5-inch FPV drones can greatly enhance your flying experience. These drones, known for their agility and speed, are a popular choice among FPV enthusiasts for racing and freestyle flying. To help you navigate the world of 5-inch FPV drones, we've compiled a list of frequently asked questions.

What is a 5 inch FPV Drone?

A 5-inch FPV drone refers to a type of quadcopter or multirotor drone that is specifically designed for FPV flying. The "5-inch" designation refers to the size of the propellers used on the drone. These drones are popular among FPV enthusiasts for racing and freestyle flying due to their agility, speed, and overall performance. 5" FPV drones are often customized and built by hobbyists, allowing them to choose specific components such as motors, ESCs (electronic speed controllers), flight controllers, and FPV cameras to suit their flying style and performance preferences.

How to Build a 5 inch FPV Drone?

To build a 5-inch FPV drone, you will need a frame, flight controller, ESCs (electronic speed controllers), motors, propellers, FPV camera, VTX (video transmitter), receiver, and a compatible radio transmitter.

How long does a 5 inch FPV Drone fly?

The flight time of a 5-inch FPV drone can vary depending on several factors, including the battery size, weight of the drone, flying style, and environmental conditions. On average, a 5" FPV drone can fly for about 3 to 8 minutes on a single battery pack. However, with efficient flying techniques and the right battery setup, it is possible to extend the flight time slightly. Pilots often carry multiple batteries to extend their flying sessions, swapping out batteries between flights.

How fast can a 5-inch FPV drone fly?

A 5-inch FPV drone can fly at speeds of up to 80-100 mph (130-160 km/h), depending on its build and setup. These drones are designed for high-speed racing and freestyle flying, making them incredibly agile and responsive in the air.

What is the range of a 5-inch FPV drone?

The range of a 5-inch FPV drone can vary depending on the radio transmitter and receiver setup, but it is typically around 1-2 kilometers.

What is the difference between a 4S and 6S battery for a 5-inch FPV drone?

The main difference between a 4S and 6S battery is the voltage. A 4S battery has a nominal voltage of around 14.8 volts, while a 6S battery has a nominal voltage of around 22.2 volts. 6S batteries can provide higher performance and longer flight times but may require different components, such as ESCs and motors, to handle the higher voltage. For more battery information about 5 inch drone, you can check the application page of 5 inch FPV drone.

Can I use a 5-inch FPV drone for aerial photography or videography?

While 5-inch FPV drones are primarily designed for racing and freestyle flying, some pilots use them for aerial photography or videography. However, they may not be as stable or suitable as larger, more specialized drones for this purpose.

How difficult is it to fly a 5-inch FPV drone?

Flying a 5" FPV drone can be challenging, especially for beginners. It requires practice and skill to master, but many pilots find it incredibly rewarding once they get the hang of it.

What is the difference between a 5-inch FPV drone and other sizes?

The main difference between a 5-inch FPV drone and other sizes is the propeller size, which affects the drone's agility, speed, and flight characteristics. Smaller drones are usually more agile but have shorter flight times, while larger drones are more stable but less agile.

How much does it cost to build a 5-inch FPV drone?

The cost of building a 5-inch FPV drone can vary widely depending on the quality of the components used. A basic build can cost around $200-$300, while a high-end build can cost $500 or more.

Where can I fly a 5-inch FPV drone?

You can fly a 5-inch FPV drone in open areas such as parks, fields, or dedicated FPV flying locations. It's important to check local regulations and fly responsibly to avoid any issues.

What is the maximum payload capacity of a 5-inch FPV drone?

The maximum payload capacity of a 5-inch FPV drone is relatively low, typically only a few hundred grams. This limits its ability to carry heavy cameras or other equipment.

Can I use a 5-inch FPV drone for indoor flying?

While it is possible to fly a 5-inch FPV drone indoors, it is not recommended due to its size, speed, and potential for damage to both the drone and surrounding objects.

What is the difference between a "bind and fly" (BNF) and a "plug and play" (PNP) 5-inch FPV drone?

A BNF 5-inch FPV drone comes pre-built and usually includes a receiver that is compatible with a specific radio transmitter. A PNP 5-inch FPV drone comes without a receiver, allowing you to use your own receiver with it.

How do I maintain and care for my 5-inch FPV drone?

Regular maintenance, such as cleaning and inspecting the drone for damage, checking and tightening screws, and ensuring all components are functioning properly, can help prolong the life of your 5-inch FPV drone.

What safety precautions should I take when flying a 5-inch FPV drone?

Always fly in open areas away from people, animals, and obstacles. Use propeller guards if flying near people or property. Follow local regulations and fly responsibly.

Can I use a 5-inch FPV drone for long-range flights?

While 5-inch FPV drones are capable of flying long distances, they are not typically used for long-range flights due to their limited battery life and range compared to larger, long-range drones.

Can I upgrade components on my 5-inch FPV drone?

Yes, you can upgrade various components on your 5-inch FPV drone, such as motors, ESCs, flight controllers, and FPV cameras, to improve performance or add new features.

Conclusion

In conclusion, diving into the world of 5-inch FPV drones opens up a thrilling realm of aerial acrobatics and racing adventures. Understanding the fundamentals, from their components to their capabilities, is key to building and flying these agile machines effectively. From the basics of assembling and configuring your drone to the nuances of battery selection and flight performance, this guide has aimed to provide a comprehensive overview of 5-inch FPV drones. As a global leader in lithium battery cell manufacturing, Grepow offers custom FPV battery for FPV drones in various specifications ranging from 1.6 inches to 10 inches. The battery capacities range from 200mAh to 8000mAh, with discharge rates (C ratings) from 15C to 250C, catering to your specific application requirements. If you have any questions or needs, please feel free to contact us at info@grepow.com.

Related Articles:

UAV Drone vs. FPV Drone: What's the Difference?

What Size FPV Drone Should I Get?

What Is a Long Range FPV Drone?

Racing FPV Drone vs Freestyle FPV Drone vs Filming FPV Drone: A Comprehensive Comparison

-

Drone Battery FAQs

What kind of battery does a drone use?

Drones typically use lithium polymer (LiPo) batteries. LiPo batteries are lightweight and have a high energy density, making them ideal for powering drones. They can also deliver high currents, which is important for the motors on a drone. LiPo batteries are rechargeable and are available in various configurations to suit different drone sizes and performance requirements.

How to choose battery for a dtone?

Choosing the right battery for your drone involves considering several factors to ensure optimal performance and compatibility. Here's a guide to help you choose the right battery:

Voltage (V): Check your drone's specifications to determine the required voltage. Most drones operate on 3.7V (1S), 7.4V (2S), 11.1V (3S), 14.8V (4S), or 22.2V (6S) batteries.

Capacity (mAh): The capacity of the battery determines how long your drone can fly. Higher capacity batteries generally provide longer flight times but may be heavier. Consider a balance between flight time and weight for your needs.

Discharge Rate (C rating): The discharge rate indicates how much current the battery can deliver. A higher C rating is suitable for drones that require high power output, such as racing drones or those with powerful motors.

Size and Weight: Ensure that the battery fits your drone's battery compartment and does not add excessive weight, which can affect flight performance.

Connector Type: Check the connector type (e.g., XT60, XT30, JST) to ensure compatibility with your drone's power distribution board.

Usage Environment: Consider the temperature and flying conditions in which you'll be using the drone, as extreme temperatures can affect battery performance.

How long should a drone battery last?

A drone battery's lifespan can vary depending on several factors, including how well it's maintained, how often it's used, and how it's charged and stored. On average, a well-maintained drone battery can last anywhere from 100 to 300 charge cycles. However, some batteries can last even longer with proper care. It's important to follow the manufacturer's guidelines for charging, storing, and using your drone battery to maximize its lifespan.

What's the longest battery life on a drone?

The longest battery life on a drone can vary depending on the drone's size, weight, and battery capacity. Generally, consumer drones have a flight time ranging from around 10 minutes to 30 minutes on a single battery charge. However, some specialized drones, such as those used for industrial or military purposes, can have much longer flight times, ranging from 1 hour to several hours. These drones often use larger batteries or other power sources to achieve longer flight times.

How can I extend my drone battery's lifespan?

To extend your drone battery's lifespan, you can follow these tips:

Avoid overcharging: Remove the battery from the charger once it's fully charged to prevent overcharging, which can damage the battery.

Avoid deep discharges: Try to avoid completely draining the battery before recharging. Instead, recharge the battery once it reaches about 20% to 30% capacity remaining.

Store at the correct voltage: Store your batteries at around 3.7V per cell, which is the optimal storage voltage for most lithium polymer (LiPo) batteries. This helps prevent them from losing capacity over time.

Store in a cool, dry place: Store your batteries in a cool, dry place away from direct sunlight and extreme temperatures. High temperatures can accelerate battery aging.

Use the right charger: Use a charger that is designed for your specific drone battery to ensure safe and efficient charging.

Balance charge regularly: If your battery is a LiPo battery, regularly balance charge it to ensure that all cells are charged evenly. This helps prolong the battery's lifespan.

Inspect regularly: Inspect your battery regularly for any signs of damage or swelling. If you notice any issues, stop using the battery immediately and dispose of it properly.

Avoid overdischarge during storage: If you're storing your batteries for an extended period, make sure to check their voltage periodically and recharge them if they drop below the recommended storage voltage.

Why do drones run out of battery so fast?

Drones can run out of battery quickly due to several factors:

High Power Consumption: Drones use a lot of power to stay airborne, especially if they're carrying a heavy payload or flying in windy conditions. This high power consumption can lead to a faster depletion of the battery.

Small Battery Size: Consumer drones are often designed to be lightweight and portable, which means they have smaller batteries with limited capacity. This smaller battery size contributes to a shorter flight time.

Flying Conditions: Flying in windy conditions or at high speeds can increase the drone's power consumption, leading to a faster depletion of the battery.

Hovering: Hovering in place requires the drone to use a constant amount of power to maintain altitude, which can drain the battery faster than flying in a straight line.

Old or Degraded Battery: Over time, drone batteries can degrade and lose capacity, resulting in shorter flight times.

How do I know when my drone battery is low?

Most drones are equipped with a low battery warning system to alert you when the battery is running low. This warning can be in the form of:

Visual Indicators: The drone's lights may start flashing or change color to indicate a low battery.

Audible Alerts: Some drones emit beeping sounds or other audible alerts to indicate a low battery.

App Notifications: If your drone is connected to a mobile app, you may receive a notification on your smartphone or tablet indicating a low battery.

Automatic Return-to-Home (RTH): Many drones have a feature that automatically returns the drone to its takeoff point when the battery is critically low. This is a safety measure to prevent the drone from crashing due to a depleted battery.

How to charge drone battery?

To charge a drone battery, follow these general steps:

Remove the Battery: Remove the battery from the drone before charging.

Use the Correct Charger: Use the charger that came with your drone or a compatible charger recommended by the manufacturer.

Connect the Battery: Connect the battery to the charger. Make sure the polarity is correct.

Plug in the Charger: Plug the charger into a power source. Some chargers may have indicator lights to show when the battery is charging and when it's fully charged.

Monitor the Charging Process: Keep an eye on the battery while it's charging. If you notice any unusual heat or swelling, stop charging immediately and disconnect the battery.

Charge Until Full: Allow the battery to charge fully. The charger or battery may indicate when it's fully charged.

Disconnect and Store Safely: Once the battery is fully charged, disconnect it from the charger and store it safely, following the manufacturer's guidelines.

Can I use any charger to charge my drone battery?

It's important to use a charger that is specifically designed for your drone battery to avoid damaging the battery or the drone. Using the wrong charger can result in overcharging, undercharging, or other issues that can shorten the battery's lifespan or cause it to malfunction. Always use the charger that came with your drone or a compatible charger recommended by the manufacturer.

How long does it take to charge a drone battery?

The time it takes to charge a drone battery depends on several factors, including the battery's capacity, the charger's output power, and the current charge level of the battery.

For example, a small drone battery with a capacity of around 1,000mAh may take about 30-60 minutes to charge fully with a standard charger. However, larger batteries with capacities of 5,000mAh or more can take several hours to charge fully.

Fast chargers are also available for some drone batteries, which can significantly reduce charging times. These chargers can charge a battery in as little as 15-30 minutes, but they may reduce the overall lifespan of the battery if used frequently.

How should I store my drone batteries?

To store your drone batteries properly, follow these guidelines:

Storage Voltage: Store your batteries at around 3.7V per cell, which is the optimal storage voltage for most lithium polymer (LiPo) batteries. Most LiPo chargers have a storage mode that can discharge or charge the battery to this level.

Temperature: Store your batteries in a cool, dry place away from direct sunlight and extreme temperatures. High temperatures can accelerate battery aging.

Avoid Full Discharge: Avoid storing your batteries fully charged or fully discharged for extended periods. This can reduce the battery's lifespan.

Regular Checks: Periodically check the voltage of your stored batteries and recharge them if they drop below the recommended storage voltage.

Storage Bag: Consider storing your batteries in a fireproof LiPo battery bag or container to contain any potential fires in case of a battery failure.

As a global leader in lithium battery cell manufacturing, Grepow offers professional customized and standard drone batteries to meet various drone applications, such as FPV and commercial drones. If you have any questions or needs, please feel free to contact us at info@grepow.com.

-

Energy Density for Batteries FAQs

What is Energy Density for a Battery?

Energy density for a battery is a crucial metric that indicates the amount of energy a battery can store relative to its weight or volume. It is a fundamental measure used to compare the performance of different battery types and chemistries. Energy density can be expressed in two main forms:

1. Gravimetric energy density, which measures energy per unit mass (typically in watt-hours per kilogram, Wh/kg),

2. Volumetric energy density, which measures energy per unit volume (typically in watt-hours per liter, Wh/L).

These measures are vital for understanding how efficient and effective a battery is in storing and delivering energy.Types of Batteries and Their Energy Densities

Lithium-ion Batteries: These have some of the highest energy densities for commercial batteries, typically ranging from 150 to 250 Wh/kg and 250 to 730 Wh/L, depending on the specific chemistry and design.

Nickel-metal Hydride (NiMH) Batteries: Generally have lower energy densities, around 60-120 Wh/kg and 140-300 Wh/L.

Lead-acid Batteries: These have even lower energy densities, around 30-50 Wh/kg and 60-110 Wh/L.

Note: The above figures get higher and higher with the times. Because battery technology is always moving forward, high energy density is now the direction of many battery R&D and production. In addition, the above energy density data is different between individual cells and battery packs.

What Does High Energy Density Mean?

High energy density in a battery means that it can store a large amount of energy in a relatively small mass or volume. This characteristic is especially important for applications where space and weight are limited. For instance, in portable electronic devices like smartphones and laptops, as well as in electric vehicles (EVs) and aerospace applications, high energy density batteries allow for longer operation times and greater efficiency without adding significant bulk or weight. Essentially, high energy density enables the design of more compact, lightweight, and efficient energy storage solutions.

Advancements in Battery Technology

Advancements in battery technology continually aim to improve energy density, enhancing the performance and practicality of various battery-powered devices and vehicles. These improvements are essential for extending the operational range, reducing the weight, and increasing the efficiency of modern electronic devices and electric vehicles.

The Higher the Battery Energy Density, Will It Be the Better?

While higher energy density generally indicates a more efficient and compact energy storage solution, it is not always the singular factor determining the "better" battery. High energy density batteries often come with trade-offs, such as reduced cycle life, higher cost, lower discharge rate, or increased safety risks due to higher reactivity of the materials involved. Therefore, while high energy density is desirable for many applications, it must be balanced with other factors like durability, safety, cost, and the specific requirements of the application. For example, an electric vehicle might prioritize a balance of high energy density and long cycle life, while a portable electronic device might prioritize compact size and safety.

Why Choose a High Energy Density Battery?

Choosing a high energy density battery is often driven by the need for extended operational time, reduced weight, and minimized space. In electric vehicles, high energy density batteries allow for longer driving ranges and better performance without significantly increasing the vehicle's weight. For portable electronics, these batteries enable devices to be smaller and lighter while maintaining or even extending battery life. Additionally, high energy density batteries are essential in applications like drones and medical devices, where every gram counts and operational efficiency is paramount. The ability to store more energy in a smaller package opens up possibilities for innovation and improved functionality across various industries.

How to Calculate the Battery Energy Density?

Calculating the energy density of a battery involves determining the amount of energy it can store and dividing that by its weight or volume.

1.For gravimetric energy density, the formula is:Gravimetric Energy Density = Wh / kg = Battery Energy / Weight = Ah × V / Kg

2.For volumetric energy density, the formula is:

Volumetric Energy Density = Wh / L = Battery Energy / Volume = Ah × V / L

Note that:Battery Energy (Wh) =Capacity (Ah)* Norminal Voltage (V)For instance, if a battery has a capacity of 12000mAh and a nominal voltage of 22.2V: Energy=12000/1000×22.2=266.4Wh (Ah=mAh/1000 ). If the weight of battery is 1700g, what's the battery energy density?

Gravimetric Energy Density=266.4/1.7=156.7Wh/kg (Kg=g/1000)Among these factors: capacity refers to the discharge capacity of the battery, voltage refers to the average voltage (for example, LFP norminal voltage is 3.2V), and mass refers to the mass of the battery cell or the battery pack. Therefore, the energy density of a single battery cell is generally higher than that of a battery pack.

For example: a lithium iron phosphate (LFP) battery produced by a certain manufacturer has a capacity of 280Ah, the mass of the battery cell is 6kg, and the platform voltage is 3.2V. Thus, the energy density of this battery is calculated as:

Energy Density = 280*3.2/6 = 149.3 Wh/kg

As an important parameter for measuring battery performance, energy density indicates that batteries with higher energy density can store more energy within the same weight or volume. This results in providing longer operating times or extended range for devices. Therefore, in practical applications, while ensuring other performance parameters, we aim for batteries with high energy density.

In all, to perform these calculations, you need to know the total capacity of the battery, typically provided in watt-hours (Wh), as well as its total weight in kilograms (kg) and volume in liters (L). By applying these formulas, one can quantitatively compare different batteries and assess their suitability for specific applications based on their energy storage efficiency.

Related Articles:

What Is a Semi-Solid State Battery?

What is a High Energy Density Battery?

Grepow High Energy Density Battery Solutions for Commercial Drone

High Energy Density vs. High Power Density Battery: What’s the Difference?