Advantages of pouch cell battery, trend and opportunities

Generally, pouch battery can apply for every application, but why cylindrical, prismatic and other cells still exist? These types have both goodness and shortcoming.

Types pf battery cell

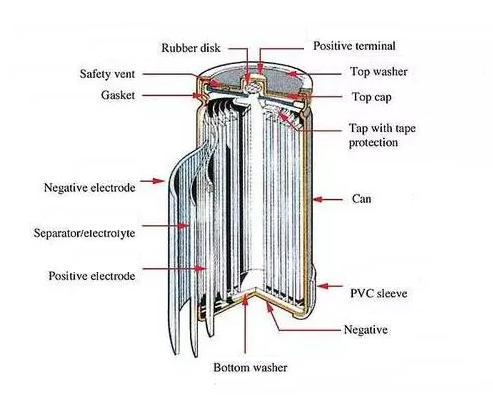

Cylindrical Cell

Cylindrical and prismatic cells are two of the most popular options on the market. Cylindrical lithium cells are easy to manufacture and mechanically stable, making them enduringly popular. They’re also very safe, if internal pressure grows too great, most cells are designed to rupture, mitigating safety hazards, and benefit from longevity, an attractive price point, and comparatively low watt-per-hour cost, making them an economical choice. [caption id="attachment_1374" align="aligncenter" width="493"]

Structure of Cylindrical Cell

Small cylindrical cells are generally used in portable technologies such as laptops and medical devices. Large cylindrical cells are popular for electric vehicles, a growing market largely driven by manufacturer Tesla.

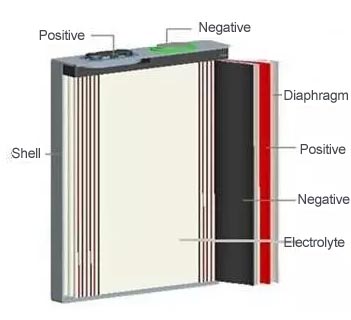

Prismatic Cell

The prismatic lithium cell’s key advantages lie in its thin profile, effective use of space; the thin, rectangular shape facilitates better layering and increased flexibility. Unsurprisingly, prismatic cells are typically found in mobile phones, tablets, and other lightweight electronic devices.

Structure of Prismatic Cell

While space efficiency makes prismatic cells highly attractive, several disadvantages exist. Prismatic cells are expensive to design and manufacture, in turn making them more expensive for consumers. They die quicker, as thermal management is less effective, and are relatively sensitive to deformation in high-pressure situations. Other drawbacks include a limited number of standardized sizes and an average higher watt-per-hour price.

Pouch Cell

In 1995, Li-polymer surprised the battery world with a radical new design, the pouch cell. The pouch cell makes the most efficient use of space and achieves a 90 to 95 percent packaging efficiency, the highest among battery packs, advantages of flexible size and safety performance. Eliminating the metal enclosure reduces weight but the cell needs some alternative support in the battery compartment. The pouch pack finds applications in consumer, special, as well as automotive applications.

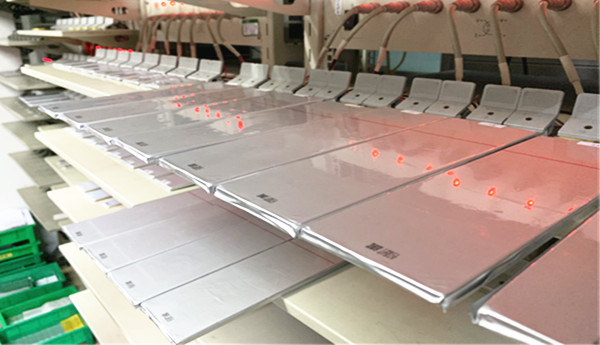

Grepow Pouch Cell Battery

The soft pack battery is packaged in aluminum plastic film. When a safety problem occurs, the soft pack battery will generally bulge, does not explode like a steel case or an aluminum case.

The shell or aluminum shell battery explodes; the weight is light, the weight of the soft pack battery is 40% lighter than the equivalent capacity of the shell lithium battery, 20% lighter than the aluminum shell lithium battery; the internal resistance is small, the internal resistance of the soft pack battery is lighter The battery is small, which can greatly reduce the self-consumption of the battery; the cycle performance is good, the cycle life of the soft pack battery is extended, the attenuation of 100 cycles is 4%~7% less than that of the aluminum shell; the design is flexible, the size can be arbitrary, and the shape can be Thinner, can be customized according to customer needs, develop new battery models.

Stacking pouch cell production please view: What is Cell Stacking Technology?

Production Technique

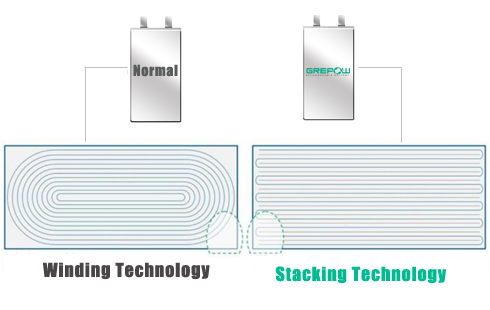

The stacking process is a lithium polymer battery manufacturing process in which a positive electrode, a negative electrode is cut into small pieces and a separator is laminated to form a small cell, and a single cell is stacked in parallel to form a large cell.

The battery cell used stacking technology has the advantages of small internal resistance, long life, high space utilization, and high energy density after group. In terms of battery performance, compared with the winding technology, the lamination stacking technology can increase the energy density of the battery by 5%, increase the cycle life by 10% and reduce the cost by 5% under the same conditions. Battery cell Stacking vs Winding Technology: https://www.grepow.com/blog/winding-and-stacking-of-cells.html

8 Advantages of choosing pouch cell battery

1.The flexibility of the Lithium Battery Pack

The completely assembled battery packs with the BMS built-in as a standard battery module. Modules can be assembled in a parallel configuration for increased capacity, or in a series configuration to increase the voltage. If needed, the BMS can offer an output cable for communication. These battery modules can be charged separately or as a whole battery pack if assembled.

2.Cycle Life

We have tested a cell that was randomly picked off the assembly line. After the accelerated equivalent of more than 4,400 charge cycles of constant cycling, this 10 AH cell still registered about 9 AH. That is a very impressive small drop of storage capacity after 12 years of about 10%.

3.Reliability

Where one cell fails, another cell takes over. You can replace single faulty units while the rest of the system continues to function flawlessly, increases the reliability of the system. As an example, a 36-volt pack at 10 AH will only require 12 pouch cells welded together. If that same application were to use 18650 cylindrical cells, it would require 72 pieces of 1.5 Ah 18650 cells welded together. In a series string if any of the 72 cells have a problem the complete pack will fail. Also, 72 cells mean 144 nodes, each node represents one potential fault. So, a cylindrical based pack is not as reliable as an electrically equivalent pouch cell pack which would only have 24 nodes. In addition, the pouch cell welding procedure is much more reliable than welding cylindrical cells.

4.Improved Energy Storage

A pouch cell’s energy storage capacity is much greater in a given physical space in comparison to cylindrical cells.

5.Safety

Whenever either pouch cells or cylindrical cells have internal problems, pressure builds and they will swell up. In those infrequent situations, pouch cells merely swell up. Cylindrical cells are traditionally encased in an iron jacket, so that when the pressure builds within a cylindrical cell whose ends are held captive by other batteries or the case, they can literally explode which could result in a dangerous safety hazard.

6.Weight

Typically, pouch cells weigh less than the equivalent prismatic or cylindrical battery. The flat pouch cell energy density is greater than other shaped cells, but its much more difficult of manufacturing stacking pouch cell battery, so this is testing the battery manufacturer's production technique.

7.Uniformity and Consistency

Grepow's entire pouch cell line is manufactured by automatic equipment, then it is manually tested to ensure that the quality of each cell is up to standard, eliminating human error in hand-made cells, and allows every cell to have uniformity and consistency.

8.Included Smart BMS

One of the other benefits of using pouch cells for smaller applications is the fact that Grepow can furnish a BMS (Battery Management System) with the pack to balance the batteries and protect them from over-charging and being over-discharged.

Pouch cell battery apply on different areas

Generally, pouch battery can apply for every applications, it depends on their shape and parameter requirements. It is no doubt that the pouch cell has many benefits than other types of cell, but it's not fit for any applications, at least for now.

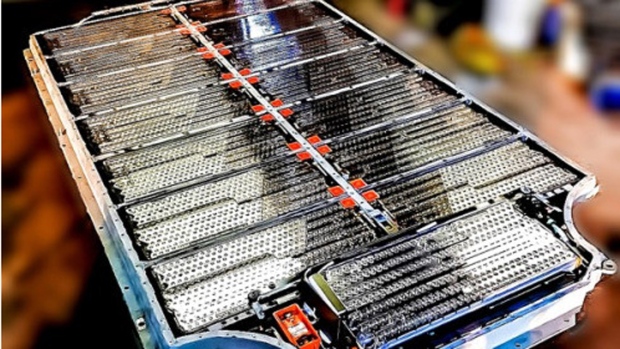

Tesla with 18650 cylindrical cell

Cylindrical Cell is still the most common type we can see, such as in the automotive industry, Tesla and BYD are still using 18650 cylindrical battery. Compared to the pouch or prismatic cells, cylindrical cells like the 18650 can be produced more quickly; so more kWh of cell produced per hour due to its configuration - another reason for a lower cost per kWh.

Another advantage of cylindrical cells over the flat cells (e.g. pouch, prismatic) is that its electrodes are wound evenly and tightly and encased in a metal casing. This minimizes electrode material from breaking up from the mechanical vibrations, thermal cycling from charging and discharging, and mechanical expansion of the current conductors inside the cell from thermal cycling.

So, with over 7,000 “18650 cells” in Tesla's small power pack, you'd think the chances of a bad connection in one of the 14,000+ interfaces is pretty high. Not if you weld the cell terminals to each other with connector tabs.

Many cells are connected in series to build up the voltage; then these series lines are connected to each other in a parallel fashion to increase amperage. So, if one cell goes bad, its impact on the entire pack is low. However, when large prismatic cells go South, it could mean a significant % of the power pack is in trouble.

Trends of the pouch cell

However, its no doubt that the market trend is the increased utilization of pouch cells, due to their increased form factor flexibility and the ability to produce sleek-looking products. The advantage of low internal resistance is also more attractive, and longer battery life also reduces the extra cost for customers to replace batteries/products. Our clients can use this as a big selling point to attract fresh users, which is perfect fit for 3C products like wearable devices, smartphones, speakers, etc. The advantages of soft pack batteries in terms of safety and energy density have also received increasing attention. From the perspective of new power battery capacity this year, soft pack batteries accounted for 30%. The penetration rate of future soft pack batteries in the field of new energy vehicles will gradually increase. From cost point of view, most of the aluminum-plastic film production areas are imported from Japan and South Korea, the proportion of Chinese-made is less than 10%, which makes it difficult to reduce the manufacturing cost of pouch cell batteries. At present, Japan's aluminum plastic film technology is indeed at the leading level in the world. After obtaining the relevant production line and patent through acquisition, the cost of aluminum plastic film can be reduced by about 20% to 30%, which reduces the cost of the pouch cell battery and meets the demand for more mass production.

Get in touch with Grepow

We are a pleasure to cooperate with you, if you interested in our rapid sampling service or other solutions, please feel free to contact us.

Related Articles

-

New Release: Tattu TA300 Multi-Channel Smart Charger for Drone Soccer

2025-09-12 -

Practical Guide to 6S LiPo Batteries for Drones & RC Models

2025-04-23 -

How to Choose a LiPo Battery Charger?

2025-04-08

Related products

-

45C High Discharge Battery - High C Rate LiPo

-

35C High Discharge Battery - High C Rate LiPo

-

High C Rate LiFePO4 Battery