How to choose Cold Storage Forklifts

With the development of the economy and the increase of the urban population, the consumption level has increased, and the demand for chilled food in society has also exploded.

The cold chain is an enormous and crucial part of America’s food supply. According to one estimate, up to 70 percent of all the food Americans consume to pass through cold storage at some point. Freezer and Cold Storage Forklifts are also an indispensable handling device, electronic forklifts are ideal for the food industry and cold chain logistics companies. So, what should you consider when choosing a frozen storage forklift? In addition to size and features, the load capacity, durability, endurance, and the charge & discharge performance of the forklift in low temperature environments. In this article, I would not share the types or brands of forklift, but more concentrated on hardware parts analysis.

The application characteristics of forklift in the cold storage

Frequent access to cold storage to carry goods

In this case, it is suitable to operate with a counterweight battery forklift and a battery hand pallet truck. It is a common method and ideal choice for plane handling, and has low waterproof requirements for the forklift. In addition, the life of forklift hardware (such as tubing, oil seals, and other components that are easily damaged) is relatively long.

Long-term processing of high shelf stacking and unloading

Due to the different working characteristics, the task of the narrow roadway stacker is to stack the goods transported into the cold storage to the high shelves, or to pick up the goods from the high shelves to the ground, so it has a relatively long operation time in the cold storage.

Use of forklift in different cold storage environments

According to the survey, it was found that most of the cold workplaces were found in cold storage warehouses with a temperature lower than -18 , and in a freezer at the processing industry with temperature ranging between -10℃ to -18℃. However, cold storages are mainly used for storage under constant temperature, ranging from -30℃ to +70℃. So, should use different levels of forklifts in different temperature environments.

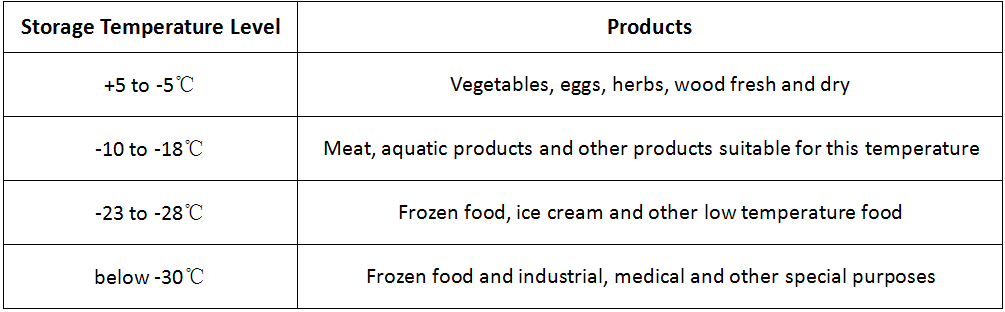

Normally, the storage level within +5 to -5℃, mainly used to store vegetables, eggs, herbs, wood fresh and dry; The second level is within -10 to -18℃, mainly used to store meat, aquatic products and other products suitable for this temperature; The low temperature within -23 to -28℃, mainly for frozen food, ice cream and low temperature food; The ultra-low temperature freezer below -30℃ is store frozen food and industrial, medical and other special purposes.

Hardware Requirements of Cold Storage Forklifts

The characteristics of battery discharge on the use of cold storage forklifts

Due to the nature of chemical of the battery, the freezing point of electrolyte is closely related to specific gravity. Under low temperature conditions, the battery cannot discharge normally.

The freezing point of the electrolyte

- The freezing point of sulfuric acid with a specific gravity of 1.13 is around -12 °C - The freezing point of sulfuric acid with a specific gravity of 1.29 is around -60 °C Below zero degree, the battery can discharge less than 60% of the total capacity.

Comparison of low temperature forklift battery and ordinary battery

Normally, the regular batteries are not suited for low-temperature environment, because the optimized temperature for lithium battery is around 20°C. In the low temperature environment, the battery can not perform its usual performance, the capacity will drop sharply, most of the batteries can not be used at low temperatures, and even there are potential safety hazards. Moreover, in terms of current battery technology, low-temperature charging is still a difficult technology to breakthrough. There are few battery manufacturers that have this kind of technology on the market, only about -20 degrees of charging can be achieved currently, but the charging time is relatively long. However, for the cold storage forklift, the temperature of the charging zone will be higher than that of the working area. In an environment of about 0 to -5 degrees, the charging efficiency can be improved a lot, and the maximum can be reached for several hours.

Precautions in the selection and use of the battery

①Select high-grade brand batteries to ensure the use of the forklift and change the battery time;

②Try to keep the battery in a full state, and ensure that the specific gravity of the battery electrolyte is in a high specific gravity state;

③The forklift and battery should be preheated before entering the cold storage;

④Keep the battery surface dry and the battery liquid level.

Create a buffer to prevent high temperature operation of the forklift

Especially in the south and the coast, the outdoor environment has a high humidity, which causes the charging area and the loading and unloading area outside the cold storage to have much higher humidity than the inside. In addition, the forklift operates in the cold storage for more than half an hour, and its surface temperature is close to the ambient temperature in the cold storage. When the forklift opens the cold storage into the charging or loading area, the surface will show condensation and condensation in a short time. Through long-term application research, there is a way to prevent the generation of large amounts of condensed water: if a buffer zone is built between the cold storage and the charging area and the loading area, after the forklift has been used for a specified period of time, the forklift opens the cold storage in the buffer zone. Rest and replace the battery to ensure that the temperature of the buffer is around 0 degrees and the humidity is controlled below 40%, which can effectively control the generation of condensed water. The humidity of the buffer zone can be controlled by means of a dehumidifier, and the temperature can be controlled by insulating the loading and unloading zone to ensure low humidity.

Cold storage vehicle use precautions

All cold storage vehicles cannot be shut down and parked in the cold storage, otherwise the hydraulic system and electrical system may be damaged.

Before entering the cold storage, all cold storage vehicles must be hydraulically and walking moved to the cold storage after the temperature of each component rises.

According to the different cold storage class, operate in the cold storage according to the standard sustainable working time.

If there is condensed water on the surface after the vehicle is out of the warehouse, it must be dry or wait for the condensed water to dry before it can enter the cold storage again.

Use cold storage special oil, regular maintenance and replacement.

Shorten the maintenance cycle of the lubrication point to prevent early wear of the lubrication point.

After the battery is discharged, it can not be vacant for a long time, timely charging and maintaining a high specific gravity of the electrolyte to prevent the battery electrolyte from freezing.

Different models cooperate to improve the efficiency of various models in the cold storage.

When the cold storage fails, the vehicle must be removed from the cold storage as soon as possible and repaired in the buffer zone or maintenance area. The cold storage type forklift is a special handling machine. Its use and maintenance methods are directly related to the service life of the forklift. The professional recommended models and the cooperation of various models and professional maintenance can ensure the effective utilization of the cold storage type forklift. Integrity and service life.

Other precautions

As the key equipment for logistics and transportation in the cold chain industry, electric forklifts play a very important role in the operation of the cold chain industry. Due to the special nature of the cold chain industry, the use of electric forklifts must take into account their ability to operate in low temperature environments. The use of electric forklifts in low temperature environments usually takes into account the following aspects.

1. Effect of low temperature environment on battery capacity

The calibration of the battery capacity is based on an ambient temperature of 20℃ and a standard pressure. The lower the ambient temperature, the smaller the actual battery capacity that can be used. In general, at a low temperature of -20℃, the actual capacity of the battery is only 80% of its nominal capacity. Therefore, an electric forklift that can meet the time requirement in a normal temperature environment may not meet the usage time requirement in a low temperature environment. The battery capacity needs to be increased appropriately.

2. Influence of temperature difference on electric forklift

In many cases, electric forklifts need to work alternately in low temperature and normal temperature environments. In this case, it is easy to generate condensed water, which may cause damage to electrical components. The design and maintenance of the forklift must take this into account, otherwise the electric forklift will most likely fail frequently and will not function properly.

3. The impact of humidity on the car body

In low-temperature cold storage, the humidity is often large. Some parts and structural parts of electric forklifts are prone to rust, which requires electric forklifts to be protected and protected against serious corrosion or even damage.

4. The requirements for anti-skid in the cold storage environment

The humidity in the cold storage is relatively large, the ground is also slippery, and there may even be ice. In this case, the forklift must have good skid resistance. Cold storage forklifts are generally equipped with non-slip tires, but this is often not enough. Since the front wheel load is large when the forklift is being loaded, and the rear wheel load is small, the friction between the rear wheel and the ground becomes small, resulting in side slipping. Therefore, the electric forklift used in the cold storage should consider the selection of the larger tonnage model when selecting, so that the rear wheel load can be maintained after the cargo is loaded, and the tire slippage is avoided.

5. Influence of low-temperature environment on hydraulic system

Hydraulic oils and hydraulic high-pressure hoses used at room temperature tend to thicken and become weak at low temperatures. Therefore, electric forklifts for cold storage must use special hydraulic oil and high-pressure hoses to avoid malfunctions and safety accidents.

6. Influence of low-temperature environment on mechanical system

Lubricating oils and greases are not suitable for use at low temperatures thus their properties will be different than normal temperatures. Therefore, special oils and greases should be used on cold storage forklift. Specially designed accessories are also required on precision components of some electric forklifts, such as sensors and precision bearings.

Related article:

Who are the leader in the battery and battery technology subfield?

Related Articles

-

Join Grepow at EUHA 2025: Discover the Next Generation of Ultra-Thin Hearing Aid Batteries

2025-10-22 -

Powering the Future of Wearables: How Grepow's Patented Curved Battery is Revolutionizing the Smart Ring

2025-10-16 -

AI Toys Leap into Innovation: Why Battery Choice Matters

2025-09-26

Related products

-

-40℃ Low Temperature LiFePO4 Battery

-

-50℃ to 50℃ Low Temperature Lipo Battery

-

-40℃ to 60℃ Low Temperature Lipo Battery