What is a smart ring battery and the manufacturing process?

What is a smart ring battery?

A smart ring battery (mostly also known as curved lipo battery) is a small

battery designed for smart rings, and they are an important part of wearable

electronics. Smart ring batteries are usually made using lithium polymer battery

technology because these batteries can be made in the desired shape and size to

fit the compact design of the ring. Smart ring batteries are needed to provide smart

rings with the necessary power to support the functions like health and exercise

monitoring, notification alerts, gesture control, and navigation and location

tracking.

What are the features of the smart ring battery?

1. High energy density: despite their small size, polymer lithium-ion

batteries are able to provide high energy density, which means they can store

more power in a relatively small space.

2. Lightweight and compact: the design of the battery must be coordinated

with the overall internal and external structural design of the ring, so they

need to be as lightweight and compact as possible.

3. Sufficient battery life: Smart rings usually require batteries to

support a longer usage time to avoid frequent charging.

4. Safety: Since batteries are close to the user's skin, they need to meet

strict safety standards to prevent overheating, short circuiting, or other

potentially dangerous situations.

Which is better, smart ring battery stacking process or winding process?

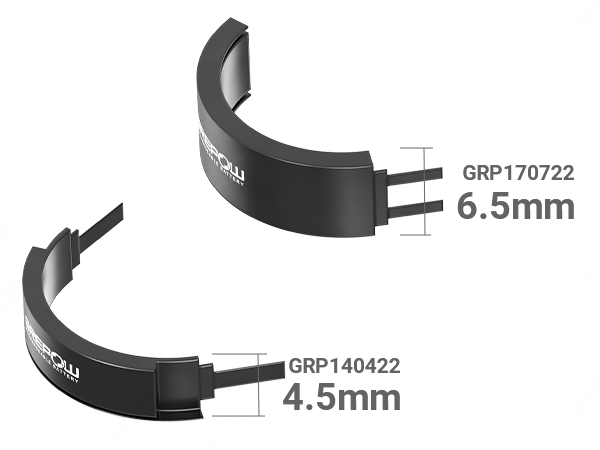

Curved lipo battery as one of the important components of the smart ring, its performance quality can not only affect the service life and duration of the smart ring, but also affect the appearance of the smart ring size and aesthetics. Since this is the case, then the following Grepow will do a comparison of the current electronic smart ring battery process.

The smart ring batteries used now belong to the high energy density lithium batteries, and there are two main production processes: stacking and winding. Let's briefly explore the differences between these two processes of batteries together.

The ring battery made by stacking process can be more tightly sealed when the battery is molded into an arc, which will not affect the beauty of the battery edges and corners by edge wrinkles, and moreover, the battery pole coating will not be damaged due to severe extrusion, which will lead to capacity degradation, internal puncture short-circuiting, and shorter service life, and other consequences.

The ring battery made by stacked piece process, the piece-shaped battery pole piece is specially made for various shapes, when the battery is made into a curved mold, the sealing edge is more tight, the edge wrinkles are close to zero, and the corners of the battery are smooth; what's more important is that the battery will not be damaged due to the extrusion of the pole piece coating, and it will avoid the problems such as capacity degradation, short circuit of the internal puncture and short service life.

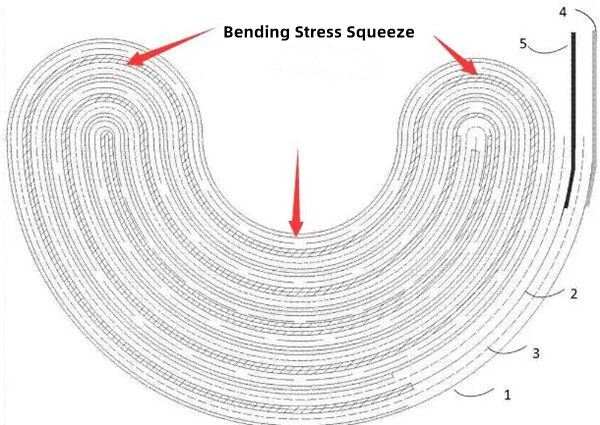

Ring batteries using the winding process, as shown above, not only have an

unsightly appearance after the bending arc is formed, but the internal structure

of the battery is likely to be damaged because of the extrusion caused by the

bending. Even if the battery is used normally at first, but after a period of

time, it is probable to be squeezed by the greater resistance of the place,

resulting in easy heating or pole piece damage, the battery capacity will be

greatly attenuated, the service life is also greatly shortened.

The above is a brief introduction to the "smart ring battery and production process comparison". When selecting ring batteries, manufacturers need to consider the battery life, charge/discharge cycle stability, battery production process and compatibility with other ring components. In addition, in order to meet the needs of different markets, battery suppliers need to offer a diverse range of products to suit different designs and technical specifications.

Related Articles:

The NeoRRow Series Curved Lithium Polymer Batteries: Coming Soon!

Key Considerations for Custom Curved Batteries You Should Know

Curved Lithium Polymer Battery - Wearable Device Mobile Power

How to custom your special-shape battery-Curved LiPo

Related Articles

-

Powering the XR Revolution: Grepow’s Custom Battery Solutions at AWE USA 2025

2025-06-06 -

Grepow to Showcase Custom Medical Battery Innovations at Medical Taiwan 2025

2025-05-21 -

Drone Training Power Guide: LiPo Batteries & Chargers

2025-05-14