Structural Advantages of Grepow Smart Drone Battery

Recently CATL announced the launch of 1000 km (620 miles) CTP 3.0 electric car battery, successfully attracted global attention; Qilin battery in safety, fast charging, durability, range, etc. are reflected in greater advantages which makes everyone feel that the new energy vehicles will be closer to the ideal ones.

And there are many people on the network asking what is the internal chemistry of the Qilin battery? This is stereotypical thinking, hydrogen batteries, sodium batteries are indeed developed by changing the battery material to break through the current performance boundaries of chemical battery energy storage, but so far these new material batteries have not yet achieved real mass production. Qilin and Tesla's 4680 battery, as the much-anticipated power batteries, both belong to the lithium-ion battery, and the former's biggest difference lies in the addition of CATL's CTP technology. It can be said that CTP technology has made it Qilin battery.

Source: Internet

What is CTP technology?

Cell to Pack is the full name of CTP, which refers to the structural design of the battery pack. It is a highly integrated structural design that greatly improves the efficiency of the cell to pack volume utilization. The energy density of NMC Qilin battery can reach 255Wh/kg, while the energy density of LFP battery reaches 160Wh/kg.

Structure Optimization is widely used.

In fact, the technology of structure optimization can be used not only in new energy vehicle power supply, but also in other fields, such as agricultural plant protection, vertical take-off and landing, transportation delivery, measurement, intelligent detection, mapping and inspection, which brings us to the UAV battery. The well-known Tattu 3.0 smart battery has also undergone iterative updates, with its structural combination continuously optimized and the overall performance of the battery significantly improved. Let's briefly talk about the structural features of Tattu 3.0 battery here.

Tattu 3.0 Drone Smart Battery For Agricultural UAV and VTOL

Structural Features of Tattu 3.0 battery

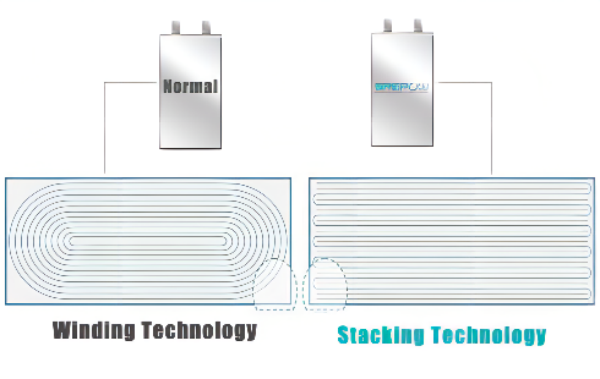

Tattu 3.0 is a professional power source for agricultural and unmanned vertical takeoff and landing drones, developed and designed by Grepow itself. First of all, the internal structure of the battery cell adopts the laminated manufacturing process and ultra-thin high-quality battery diaphragm, which has batter space utilization and higher charge/discharge multiplier compared to the winding process, among which the The NMC 811 cell is made with Grepow's stacking process, and its energy density even reaches 275Wh/kg.

Stacking vs Winding Process

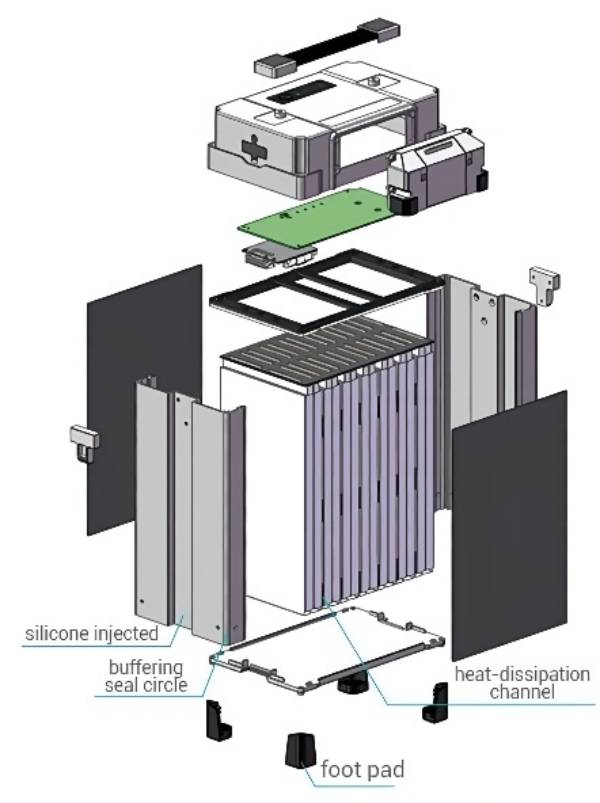

Vibration damping devices are provided between the cells and the cells and between the cells and the case to reduce or eliminate shocks wherever they occur. Each anti-vibration system is isolated from each other, preventing interconnection and allowing partial shocks to be contained within a narrow range, enhancing the shock and vibration resistance of the battery pack and improving the safety of the battery during use.

Structure of Tattu 3.0 Battery

On the other hand, the Tattu 3.0 battery is designed so that heat is transferred from the high concentration area to the low concentration area, so that it does not overheat, while allowing the battery to operate in optimal condition. At the same time, this Tattu 3.0 UAV smart battery is matched with a high-precision AFE front-end acquisition chip and a dust and water-resistant casing material to enhance the battery's life and durability.

All in all, battery is the power reserve that makes electronic products convenient. Battery technology includes both the development of materials and the advancement of manufacturing process and optimization of battery pack structure. In the future, battery manufacturers will also continue to strive to push more boundaries to develop and manufacture batteries that are friendly to both humans and nature.

More you may like:

Winding VS Stacking – Which is Better for Lithium Battery?

Related Articles

-

Powering the XR Revolution: Grepow’s Custom Battery Solutions at AWE USA 2025

2025-06-06 -

Grepow to Showcase Custom Medical Battery Innovations at Medical Taiwan 2025

2025-05-21 -

Drone Training Power Guide: LiPo Batteries & Chargers

2025-05-14

Related products

-

Tattu Plus 6S 10000mAh 22.2V 25C Lipo Smart Drone Battery

-

Tattu Pro 14S Lipo 22000mAh 51.8V Smart UAV Drone Battery Pack

-

Tattu Plus 1.0 Compact 12S 16000mAh 44.4V 15C Lipo Smart Drone Battery