What is the packaging technology of soft pack Li Ion battery?

Soft pack lithium-ion batteries are always found in consumer electronics, as UAV/drone batteries, and the high-performance batteries of RCs, for special, and automotive industries.

What is a soft pack lithium-ion battery?

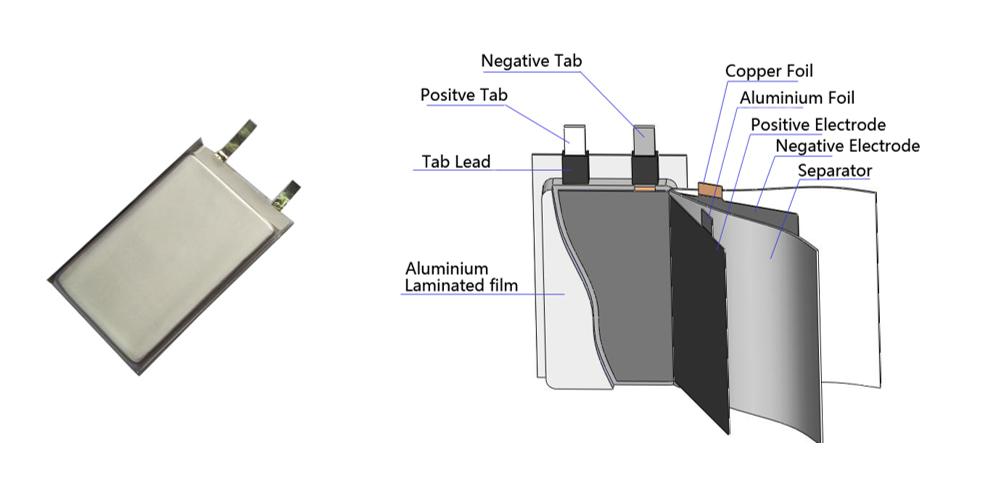

A Lithium-ion battery consists of positive electrode, negative electrode, electrolyte, diaphragm, etc. and shell packaging. According to the different shell packaging materials, the overall packaging of lithium-ion battery shell can be divided into steel shell, aluminum shell, and soft-coated aluminum-plastic film. And soft pack lithium-ion batteries (also named pouch cell batteries) are usually rechargeable lithium-ion batteries, typically lithium polymer whose highlights are lightweight, shape customizable, large capacity, etc. the choice of aluminum-plastic composite film (commonly known as aluminum-plastic film).

The soft pack battery structure

This article is talking about what and how the aluminum-plastic film packages Lithium-ion batteries.

The meaning and purpose of packaging

The significance and purpose of soft pack lithium-ion battery packaging are to completely isolate the inside of the cell from the outside using a high barrier flexible packaging material, leaving the inside in a vacuum, oxygen-free and water-free environment. There are dynamic electrochemical reactions inside lithium-ion batteries, which are sensitive to water and oxygen. If water and oxygen meet the electrolyte, they will react with the lithium salt in the electrolyte to produce a large amount of HF, which will affect the electrochemical performance (such as capacity and cycle life) of the cell. Note: Hydrofluoric acid (HF) is a contributor to the degradation and shortened life of many energy storage devices that use fluorinated organic electrolytes, such as lithium-ion batteries.

Packaging materials and packaging design

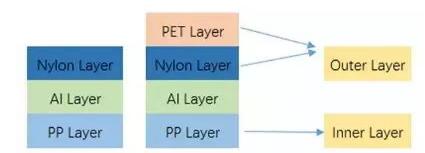

Aluminum plastic film material and structure

The outer layer: generally nylon layer, its role is to protect the middle layer, reduce scratches and dirt soaking, ensure that the battery has a good appearance, the second is to prevent the penetration of air, especially oxygen, to maintain the internal environment of the battery cell, the third is to ensure that the packaging aluminum foil has good deformation capacity. Sometimes PET is used instead of nylon to have better chemical resistance, but this will lead to a reduction in the depth of the punch pit of the aluminum-plastic film.

Structure of Aluminum plastic film

The middle layer: with a certain thickness and strength to prevent water vapor penetration and external damage to the core, the most mainstream is made of aluminum foil.

Inner layer: mainly plays the role of encapsulation, insulation, preventing Al layer from contacting with electrolyte, etc., mainly using PP material.

Decorative or special protective layer: In order to improve the luster of battery appearance, sometimes a matte layer is added outside of PET/nylon, but this will lead to a significant increase in the price of aluminum-plastic film.

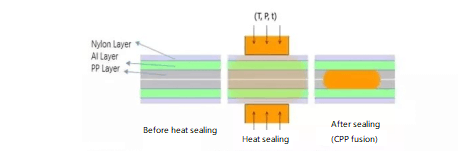

What is the principle used for aluminum-plastic film encapsulation?

By and large, it relies on mechanical high temperatures, typically 230°C (446°F), to fuse together. The two PP layers face each other, and by giving a certain amount of heat to the Nylon layer, the heat is transferred to the PP via the Al layer, and the two PP layers fuse together under the combined effect of a certain temperature, pressure, and time.

Hot pressing processes of Aluminum plastic film

Encapsulation process

PP top-sealing: packaging foil is folded & aligned, Tab position is fine-tuned, core is loaded and aligned, and then heat sealing is performed. The top-sealing process is the most difficult process to control for the whole package, the main difficulties include:

1) Packaging foil alignment (cutting, folding).

2) TAB position control (core width and center distance, edge distance).

3) Core feeding positioning (unsealed area of core)

4) Heat sealing head structure design (head width, Stopper, head recess depth).

5) Optimization of heat sealing process conditions (time, temperature, pressure, etc.).

p Side seal: It is to encapsulate the core after completing the top seal. The process control is mainly for the optimization of core positioning and heat-sealing process conditions.

p Corner sealing: The purpose is to prevent the seal from breaking at the corners of the package foil pair fold. The requirement of corner sealing is just to fuse the two layers of packaging aluminum foil together to prevent the stress concentration caused by bending. Process control is mainly the optimization of core positioning and heat-sealing process conditions.

p Vacuum encapsulation: The purpose is to seal the airbag after liquid injection to prevent electrolyte leakage and the entry of water vapor. The requirement of vacuum encapsulation is only sealing, and the process control is mainly the optimization of core positioning and heat-sealing process conditions.

ppSecondary encapsulation (Degassing): It is the process of venting and sealing the cores after chemical formation. Compared with side sealing, it requires airbag puncture and encapsulation under vacuum conditions.

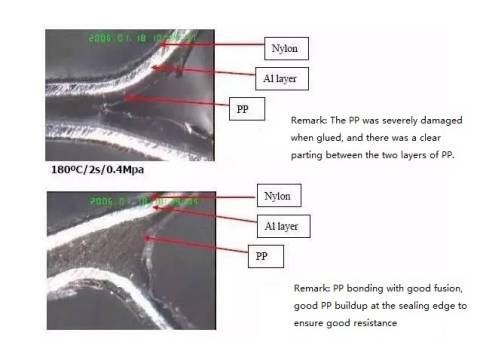

Encapsulation parameters and effects

1.Temperature (melting point of PP and outer nylon, head structure and heat dissipation)

2.Time (heat transfer and PP fusion)

3. Pressure (PP lamination, affecting melt and heat transfer)

4. Vacuum degree (mainly vacuum resting and degassing process)

Encapsulation parameters and effects

Effect confirmation

1. Encapsulation parallelism check (on the basis of stopper parallelism ok, encapsulation, tear open the encapsulation surface to observe foil melt glue showing milky white, seamless encapsulation bad place).

2. Tension test (including pole lug position and side seal position) Unsealed area inspection (visual inspection, including the top seal, side seal, and bottom seal of the internal and external unsealed area, check the internal PP situation)

3. Sealant exposed inspection (visual inspection, mainly negative pole lugs)

4. Resistance test (inspection after top and side seal including Al layer between positive and negative pole lugs, negative pole lugs, and Al layer in the pocket bag, an inspection of the negative pole and Al layer in the pocket bag after degassing).

Related Articles

-

LiPo battery vs LiHV battery: what’s the difference?

2025-07-16 -

Building an FPV Drone: A Deep Dive into the Technology

2025-06-30 -

What is an 8S LiPo Battery?

2025-06-20

Related products

-

-40℃ to 60℃ Low Temperature Lipo Battery

-

45C High Discharge Battery - High C Rate LiPo

-

High C Rate LiFePO4 Battery