What is Compaction Density?

Introduction

The compacted density is divided into a negative density Anode density and a positive compact density. In the design of lithium-ion batteries, compaction density = areal density / (thickness after pole piece rolling - thickness of current collector), unit: g / cm3, which is the basic definition.

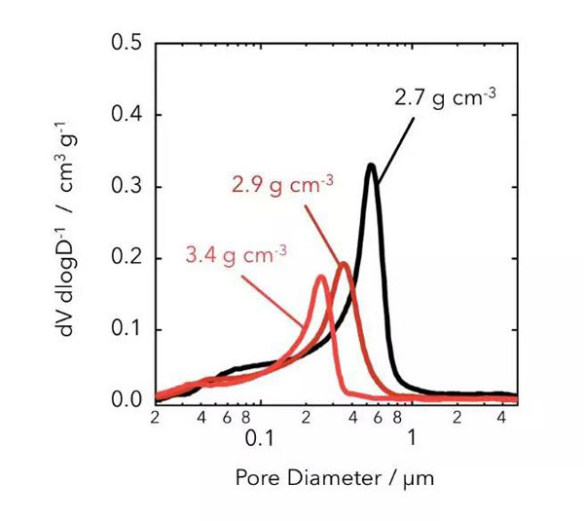

In the fabrication of lithium-ion batteries, compaction density has a large impact on battery performance. It has been proved by experiments that the compaction density is closely related to the sheet specific capacity, efficiency, internal resistance, and battery cycle performance. Finding the optimal compaction density is important for battery design. In general, the higher the compaction density, the higher the capacity of the battery can be made, so compaction density is also considered as one of the reference indicators of material energy density. The compaction density is not only related to the size and density of the particles, but also related to the gradation of the particles. Generally, the compact density has a good normal distribution of particles. It can be considered that under certain conditions of the process conditions, the greater the compaction density, the higher the capacity of the battery. Compaction density is an important parameter in the production of lithium-ion batteries. In order to increase the energy density, we generally want to increase the compaction density as much as possible. The figure below shows 2.7, 2.9 and 3.4g/ under the control of the same thickness. The change of the micropore size inside the electrode at the compacting density of cm3 can be seen from the figure, as the compaction density is gradually increased, the size of the micropores inside the electrode is also gradually reduced.

(The pictrue from Internet. All rights reserved.)

In the unrolled electrode, only 50% of the space is occupied by the active material, increasing the compaction density can effectively increase the volumetric energy density and weight energy density of the electrode, but this also affects the electrode structure, such as pores. The rate, specific surface area, pore size distribution, and curvature also affect the distribution of binder and conductive agent in the electrode, which has a significant effect on the electrochemical performance of the lithium-ion battery.

Relationship between high rate battery and compaction density

The higher the compaction density of the high-rate battery, the smaller the liquid absorption value of the battery, and the direct relationship between the internal structure of the electrode and the positive and negative electrodes of the battery are of different shapes and sizes. The material is evenly arranged on the surface of the aluminum foil and copper foil. The difference in compaction density changes the distance and gap between the particles. The greater the compaction density, the tighter the contact between the particles, and the smaller the distance and gap between the particles. The electrolyte is in a liquid state, and when a sufficient amount of electrolyte is injected, the electrolyte will penetrate into the gap between the particles to a saturated state. The smaller the distance and the gap between the particles, the smaller the area in contact with the electrolyte, the smaller the space for absorbing the electrolyte, and the corresponding amount of electrolyte absorbed, which means that different compaction densities affect the battery absorbance. The main reason. Of course, different raw materials will also cause different aspiration values due to differences in particle morphology and structural grain size, and the impact on this aspect remains to be further studied.

Effect of compaction density on high rate battery capacity

The compaction density of the high-rate battery affects the battery capacity and specific energy, the same capacity design, the battery quality is close; the compaction density is different, the thickness of the pole piece is different, and the thickness of the assembled battery is different. Different compaction densities have a great influence on the thickness of the battery, and the maximum thickness difference is 0.7mm, which is 10% of the thickness of the battery; the effect of different compaction density on the battery lC capacity is not obvious; the thickness change has a larger energy to the battery volume ratio. The effect of compaction density on the volume of the battery to change the volumetric specific energy of the battery to some extent, from this point of view, increasing the compaction density is one of the effective ways to increase the volumetric specific energy of the lithium-ion battery.

Effect of compaction density on the internal resistance

The effect of compaction density of high-rate battery on the internal resistance of the battery, the effect of different compaction density on the internal resistance of the battery, the increase of compaction density can reduce the internal resistance of the battery to a certain extent, and the influence law of positive and negative electrodes is similar. The internal resistance of the battery reflects the difference in the internal conductivity of the battery to a certain extent. Under the same conditions of the formulation and the raw material, the compaction density increases, the distance between the raw material particles decreases, the contact probability increases, and the contact area between the particles increases. Large, conductive bridges and channels increase, battery impedance decreases, and internal resistance decreases.

Effect of compaction density of high-rate battery on high-rate discharge performance of battery

Excessive or too small compaction density will affect the rate discharge performance of high-rate batteries. Therefore, in order to achieve an ideal high current discharge performance, there is an optimum range of compaction density.

1.The compaction density is too large, the distance between particles is reduced, the contact is tighter, and the electron conductivity is enhanced, but the ion moving channel is reduced or blocked, which is not conducive to the rapid movement of a large number of ions, thereby limiting its large current discharge and polarization during discharge. Increase, the discharge voltage decreases, and the discharge capacity decreases;

2.The compaction density is too small, the distance between particles increases, the ion channel increases, and the liquid absorption of the electrolyte increases, which is beneficial to the rapid movement of ions. However, due to excessive particle spacing, the contact probability and contact area between particles are reduced, which is not conducive to electrons. Conductive, the conductivity is reduced to affect the large current discharge, and the discharge polarization is increased.

Therefore, the proper range of compaction density can ensure sufficient contact between the particles without blocking the ion moving channel, while ensuring good electrical conductivity and rapid ion movement of the electron during large current discharge, reducing discharge polarization and increasing discharge platform voltage.

Effect of compaction density on high-rate cycle performance of batteries

There are many factors affecting the cycle performance of high-rate batteries. From the perspective of the influence of different compaction densities on high-rate cycling performance, the degree of influence is obvious. In addition, the difference in the liquid absorption value, internal resistance, high rate discharge performance and median voltage of the battery will affect the high rate cycle performance of the lithium-ion battery, and these factors have a certain correlation with the compaction density, so compaction Density has a complex effect on the high-rate cycling performance of lithium-ion batteries.

Learn more about battery

Keep an eye on Grepow's official blog, and we'll regularly update industry-related articles to keep you up-to-date on the battery industry.

Grepow: https://www.grepow.com/

Grepow Blog: https://www.grepow.com/blog.html

Related Articles

-

The Ultimate Guide to Grepow Jump Starter

2025-03-27 -

How to Choose Lithium Batteries for Cold Weather?

2024-09-19 -

Next-Generation eVTOL Battery Technology

2024-08-22

Related products

-

-30℃ 5C Low-Temperature High Discharge Battery

-

50C High Discharge Battery - High C Rate LiPo

-

45C High Discharge Battery - High C Rate LiPo

-

High C Rate LiFePO4 Battery