What is Abnormal Voltage Gap? - Battery Voltage Gap

What is Voltage Gap?

Voltage Gap is the voltage differentials of different cells when the battery pack achieve in multi- parallel and series. Normally, the static voltage gap is within 0.05V, and the dynamic is within 0.1.

In addition to the voltage, the cell also has a difference in capacity or volts, we also need to know.

Why Does Voltage Gap Cause?

A single battery cell does not have a voltage gap, but in order to achieve a higher discharge rate, capacity, etc., we assembled into a battery pack using a multi- parallel and series. Just as there are no two identical leaves in the world, there is no way to achieve the same between two cells, so we allow a certain range of differences, which is the reason for the gap caused. However, how to control the gap in these specifications is one of the factors that determine an excellent battery manufacturer. The process of producing the cell and the quality monitoring can control the voltage gap to the nearest range.

What is Abnormal Voltage Gap?

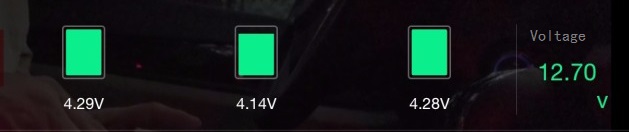

Abnormal Voltage Gap means that the voltage gap of the battery pack has exceeded the acceptable range. When we fully charge the battery, we can check the voltage of the battery through some instruments or equipment, just like the battery in the picture below. In the battery pack, it can be seen that the voltage of one of the cells is different from the other two. This will lead to uneven use of a certain cell, accelerate the aging, the device may not start properly, and may even cause some safety hazards.

Three key points of Voltage Gap:

The Voltage Gapaffects the life cycle of lithium battery, the good battery cells can control the gap to extremely low.

Normally it should be around 0.02.It has a great relationship with electrical endurance, and the battery with normal voltage gap has a longer discharge time.

Voltage Gap is an important reference for measuring the quality of lithium batteries and the quality of battery cell.

There are three reasons for the anomaly voltage gap:

Initial cell SOC difference in the production process

The maximum capacity difference of the battery

The PACK process is abnormal.

What are the problems caused by abnormal voltage gap?

For a battery pack, the voltage difference between the individual cells is one of the main indicators of consistency. The smaller the voltage difference is, the better the consistency of the battery core is, and the battery pack has better discharge performance. On the contrary, the greater the voltage difference, the worse the consistency of the battery core, and the discharge performance of the battery pack is also negatively affected. The direct effect is that the battery pack discharge energy is insufficient and gradually deteriorates as the number of cycles increases. Therefore, in the PACK process, it is an important issue to control the voltage gap between the individual cells of the battery pack.

How to detect if the voltage gap is abnormal?

Normally, we can only monitor the condition of the battery through the battery management system (BMS). After the battery is fully charged and discharged, it will be left to check whether the data of the battery pack is balanced. In addition, during the use of the battery, the voltage of the battery core will continue to drop. When the battery core is in an abnormal pressure difference, the BMS can also prompt the user to have an abnormality. At this time, we need to take some actions.

What should you do when find an anomaly?

Use low power charging

Charge the battery with a low current charger to return the battery to normal voltage levels.

Single battery cell charge/discharge

Due to the abnormal PACK process, there is a large voltage gap appear after the battery module is manufactured. At this time, the use of the power-filling cabinet to charge/discharge the single cell is the most common method in production. Because the voltage of the battery is close to the empty state, the relationship between the voltage and the SOC changes is obvious. When the power supply cabinet is used to charge/discharge a cell, the battery pack power needs to be emptied first, and the maximum voltage of the monomer is lower after standing for 10 minutes. 3.2V (General lithium iron phosphate battery voltage >3.2V, its SOC and voltage change relationship is not obvious), and then according to the SOC-OCV comparison table for a single series of charge/discharge operation, the voltage of each series cell is controlled Within the standard range.

P.S. When replenishing a single cell of batteries, carefully remove the BMS to prevent damage to the BMS components.

BMS - Voltage Equalization System

The voltage equalization system is an independent device installed on the battery pack. The main principle is to charge/discharge the single-string battery with abnormal voltage through the BMS control system switch. Depending on the energy storage or energy consuming components selected for the equalization circuit, the battery in series equalizer is mainly divided into a switch resistor shunt equalizer, a capacitor equalizer, an inductor equalizer, an LC oscillating circuit equalizer, and a flyback transformer equalizer. The following figure shows the design of a vehicle-mounted capacitor equalizer. Each string of cells is connected in parallel with a capacitor and controlled by a MOS switch. If you are interested in our products, please don’t hesitate to contact us at any time! Email: info@grepow.comGrepow Website: https://www.grepow.com/

Related Articles

-

New Release: Tattu TA300 Multi-Channel Smart Charger for Drone Soccer

2025-09-12 -

Practical Guide to 6S LiPo Batteries for Drones & RC Models

2025-04-23 -

How to Choose a LiPo Battery Charger?

2025-04-08

Related products

-

3.95V/4.45V High Voltage Cells

-

3.8V/4.35V High Voltage Cells

-

GRP1254 Series Rechargeable Lithium-Ion Button Cell Battery