Powering Aerial Artistry: Grepow Battery Solutions Behind Drone Light Shows

Powering Aerial Artistry: Grepow Battery Solutions Behind Drone Light Shows

Drone light shows have become a new global phenomenon, lighting up the skies at major celebrations, brand promotions, and cultural events. Behind the beauty and precision of every synchronized formation lies a silent but vital force — the battery.

As a leading battery cell manufacturer and solution provider, Grepow delivers thigh-performance light show drone batteries and power systems that enable the world’s most advanced drone light shows. From energy-dense LiPo cells to intelligent charging technologies, Grepow’s innovations ensure every drone performs safely, efficiently, and in perfect harmony.

The Power Challenges Behind Every Drone Light Show

Drone light shows push battery performance far beyond standard UAV applications. Each performance requires energy systems that balance precision, endurance, and reliability under dynamic flight conditions.

Synchronization Precision

Thousands of drones must operate in perfect coordination. Any variation in voltage or discharge rate can disrupt the aerial choreography.

Long-Lasting Endurance

Extended shows demand consistent, stable power delivery. High energy density and optimized discharge curves are essential to sustain intricate formations.

Fast Turnaround & Operational Efficiency

Frequent performances call for safe, efficient charging and rapid battery replacement to minimize downtime and maintain show schedules.

All-Weather Reliability

Outdoor events often face high humidity, heat, or sub-zero temperatures, requiring cells capable of stable output in extreme environments.

Safety and Stability Above All

Operating above large crowds demands batteries engineered with robust protection mechanisms to prevent voltage drops, overheating, or failures.

Custom Energy Management

Each show differs in scale, drone configuration, and duration — necessitating customized battery and charging strategies, not one-size-fits-all solutions.

Grepow: Engineering the Power Behind Performance

Grepow’s strength lies in its vertically integrated R&D and manufacturing capabilities. From material formulation and electrode design to pack integration and testing, every process is controlled to guarantee consistency and reliability across fleets of thousands of drones.

High Energy Density LiPo Cells

Through Grepow’s proprietary stacking process, our LiPo cells achieve greater capacity and discharge stability — extending flight time and ensuring smooth synchronization across drone formations.

Smart Charging Technology (G-Tech)

Our intelligent charging systems automatically optimize the charging curve, shortening ground preparation time and enhancing battery cycle life — ideal for high-frequency light shows.

Unmatched Consistency

Grepow applies strict cell matching and quality control protocols, ensuring every pack delivers identical voltage, resistance, and capacity — the foundation for precise synchronization.

Comprehensive Safety Engineering

Each battery is designed with advanced safety mechanisms, including multiple protection layers, temperature monitoring, and stable chemical composition for secure operation.

Wide Temperature Range Reliability

Engineered to perform from -40°C to +60°C (temperature optional), Grepow batteries maintain stability in both hot desert nights and freezing winter skies.

OEM & Custom Solutions

With deep engineering expertise, Grepow provides high-performance cells, BMS integration, and pack configurations tailored to specific drone platforms and show requirements.

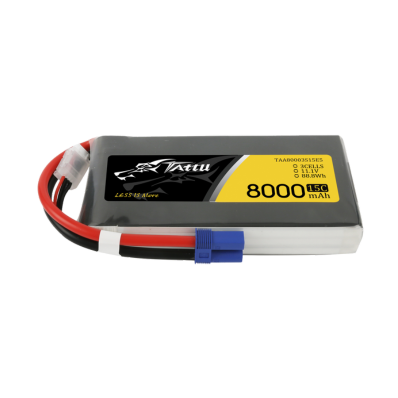

Tattu: Powered by Grepow’s Core Technology

As one of Grepow’s sub-brands, Tattu represents the application of our advanced UAV battery technologies in the professional drone performance industry.

Trusted by leading drone light show operators worldwide, Tattu batteries integrate Grepow’s high energy density cells, G-Tech smart charging systems, and stringent safety designs — providing the reliability and performance demanded by aerial show professionals.

From public celebrations and cultural events to corporate showcases, Tattu powered by Grepow delivers consistent, brilliant performances that illuminate the skies.

Enabling the Future of Drone Light Shows

Every successful drone light show begins with dependable power.

Through continuous R&D, precision manufacturing, and global OEM collaboration, Grepow empowers drone light show teams and manufacturers to unlock new levels of creativity, efficiency, and safety.

Grepow — the power behind every illuminated sky.

FAQ — Frequently Asked Questions

1. What is the Minimum Order Quantity (MOQ)?

The MOQ depends on the battery type, size, and specifications you require. For standard off-the-shelf models, MOQs are relatively low. For bespoke or highly customized packs, MOQ varies according to tooling, cell format, and production planning. Please contact our sales team with your specific requirements so we can provide an accurate MOQ and lead time estimate.

2. Do you supply compatible chargers, and how many channels do they support?

Yes — Grepow supplies matching intelligent chargers engineered to work with our batteries. Charger configurations vary by operational scale: we provide single- and multi-channel chargers, as well as high-density multi-slot systems tailored for rapid turnaround when managing large fleets. Channel counts and charger specifications are selectable based on fleet size and charging workflow. Contact us to discuss the optimal charger configuration for your operations.

3. Can you provide customized smart batteries with integrated BMS?

Absolutely. Grepow delivers custom smart battery packs with integrated Battery Management Systems (BMS) that monitor cell voltage, temperature, state of charge, and cycle count. We support a variety of communication protocols (CAN, UART, SMBus, etc.) and can tailor BMS functionality to your telemetry and safety requirements. Our engineering team will collaborate with your systems integrators to ensure seamless BMS integration.

4. Can you provide batteries specifically formulated for low-temperature environments?

Yes. Grepow’s R&D team has extensive experience developing low-temperature cell formulations. While our standard battery operating range is typically -20°C to +60°C, we offer low-temperature formula options that extend performance to ranges such as -40°C to +60°C or -50°C to +50°C, depending on the chemistry and pack design. Exact performance specifications and trade-offs (capacity, internal resistance, cycle life) depend on the chosen formulation and pack configuration — please contact us with your environmental and performance requirements for detailed recommendations.

Related Articles

-

Powering the Future of Wearables: How Grepow's Patented Curved Battery is Revolutionizing the Smart Ring

2025-10-16 -

Grepow Battery Announces Manufacturing Agreement with Powerbanc Group

2025-09-30 -

AI Toys Leap into Innovation: Why Battery Choice Matters

2025-09-26

Related products

-

Tattu 4S 6750mAh 14.8V 25C Lipo Drone Battery

-

Tattu G-Tech 4S 5200mAh 14.8V 35C Lipo Drone Battery

-

Tattu 3S 8000mAh 11.1V 15C Lipo Drone Battery