Battery Experts - High capacity formulations for mapping drone battery

Battery Experts - High capacity formulations for mapping drone battery

Construction projects are complex and require a lot of time and money from several contractors and hundreds of workers to complete.Previously, building mapping needed to be done by helicopter or site survey. Today, mapping drones provide standardized, detailed site maps, providing reliable data for both internal and external stakeholders to keep projects on time and budget savings. The building area is complex and vast, and mapping drones requires long hours of operation, which increases the demand for the drone battery’ capacity. Battery manufacturers will invest heavily in mapping drone battery formulations to develop technology that they hope will produce a small but large-capacity drone battery. What is the direction of large-capacity formulation research and developme

Correct selection of the positive material for drone battery

As a positive active substance selection has its special requirements. The positive material has a large Gibbs free energy to maintain a large potential difference with the negative material, providing the battery operating voltage (high C-rate power). The Gibbs freedom in the lithium-ion embedding reaction can change small. This means that the lithium-ion embedding volume is large and the electrode potential is less dependent on the embedding amount, which ensures that the lithium battery operates at a stable voltage. Positive materials need to have a large aperture structure, so that in the process of charging and discharging, lithium ions can be freely embedded and escape. Lithium-ion embedding or disembedding range is relatively wide.

The positive material has a large interface structure and rich apparent structure, which increases the spatial position of lithium embedded in discharge and increases the amount of lithium ion embedded. Positive material and electrolyte have good compatibility, high thermal stability, to ensure the safety of the battery. The chemical and physical properties of positive materials are homogenous and their kinetic properties are minimal to ensure the good cycle life of the battery.

Increase the number of embedded lithium ions of negative materials

Currently commercial drone battery negative materials are used in carbon materials, including graphite carbon materials such as graphite intermediate phase carbon microbeads and some thermally resolved hard carbon. At present, the actual ratio of these carbon materials generally does not exceed 400mA.h/g. The actual volume ratio of positive material is higher than the positive pole of capacity. Therefore, to further improve the battery ratio energy, improve the performance of the number of embedded lithium ions of negative materials is the key to research and development.

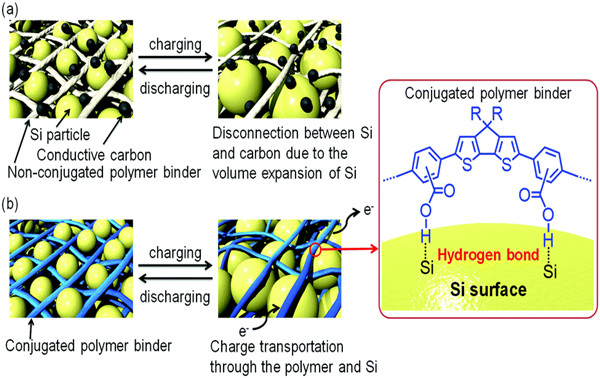

At present, a single material can not fully meet the needs. Carbon materials have good cycle properties, but they are lower than capacity. Other electrochemical properties of carbon materials with higher capacity are impaired. Alloy materials have a high energy ratio, but due to the large volume expansion in the inlay lithium process, the material's circulation performance is far from sufficient. In this way, the combination of the advantages of various materials, purposefully composite of various materials, to avoid their own shortcomings, the formation of composite negative materials is a reasonable choice.

Electrolytes improve the high and low temperature properties of drone battery

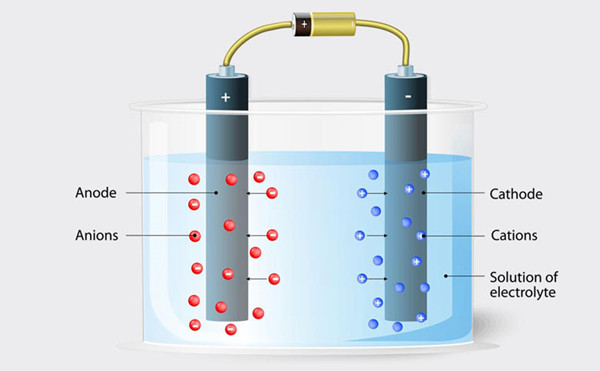

Lithium battery electrolyte is the carrier of ion transmission in the battery. It is generally composed of lithium salts and organic solvents. Electrolyte in the lithium battery between the positive and negative poles play the role of conduction ions, lithium-ion battery to obtain high voltage, high energy and other advantages of the guarantee. Electrolyte is generally composed of high-purity organic solvents, electrolyte lithium salts, necessary additives and other raw materials, under certain conditions, in a certain proportion of the formulation.

The electrolyte chemistry and electrochemical stability of the drone battery are good. In other words, it does not react to electrode materials of the battery system, such as positive, negative, collecting fluids, diaphragm binders, etc. The electrolyte has high ion conductivity, high dielectric constant, low viscosity, and low resistance to ion migration. The boiling point of the electrolyte is high and the freezing point is low. It is liquid in a wide temperature range, with a general temperature range of -40 to 70 degrees C, and is suitable for improving the high and low temperature characteristics of drone batteries.

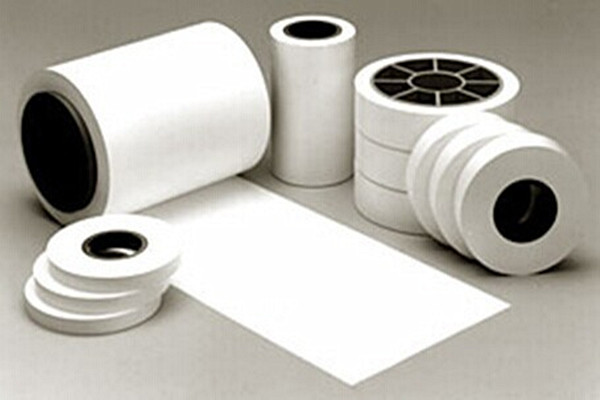

Diaphragm protects drone battery when they are charged and discharged

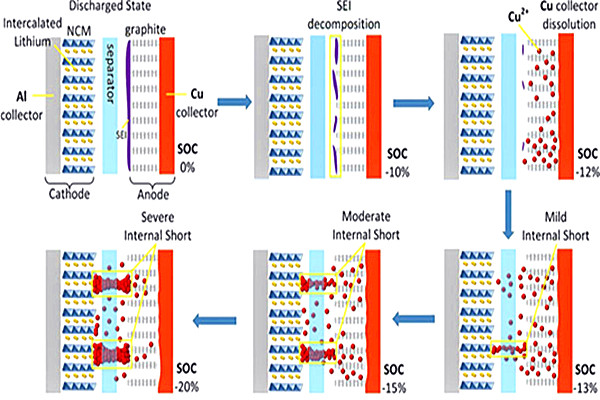

In the diaphragm of a drone battery, a protective belt can also be designed for overcharging and short circuiting. This means that the diaphragm suddenly increases at about 130 degrees Celsius, preventing lithium ions from transmitting between electrodes. When the diaphragm is above 130 degrees, the safer the protective belt, the better the diaphragm's role will be. When the diaphragm breaks, there may be direct contact between the electrodes, a reaction that releases huge amounts of heat.The mask of the diaphragm is popular to characterize it by heating the diaphragm to a high temperature and then measuring its resistance.

Snout ingress is a very useful and effective mechanism for limiting the temperature and preventing short-circuiting the battery. The shading flow temperature is usually selected near the polymer diaphragm melting point. At this temperature, the resistance of the battery also increases dramatically, and the channel of current in the battery is blocked, thus preventing the further occurrence of electrochemical reactions in the battery. As a result, the battery reaction can be interrupted before it explodes.

New indicator of binder for drone battery

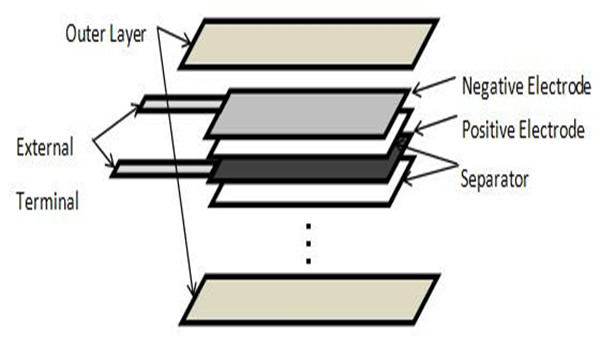

In lithium batteries, the large area of the electrode is required because of the use of electromechanical solutions. Grepow uses stacking technology when producing drone batteries, and new indicators are proposed for the binders used in electrode manufacturing processes. Binders can maintain a fairly high thermal stability when heated to 130 to 180 degrees Celsius during drying and decontamination.

The binders can be wetted by electromechanical solution, with good processing performance and relatively high electrical conductivity of electronic ions. Binders are stable in additives in electrolytes such as LiClO4, LiPF6, and by-products LiOH, LiCO3, etc. Adhesives are not easy to burn and have good reprocessing properties.

Keep an eye on Grepow’s official blog, and we’ll regularly update industry-related articles to keep you up-to-date on the battery industry.

Grepow: https://www.grepow.com/

Grepow Blog: https://www.grepow.com/blog.html

Related Articles

-

Powering Aerial Artistry: Grepow Battery Solutions Behind Drone Light Shows

2025-10-27 -

Vatican Drone Show: Where Technology Meets Faith

2025-09-15 -

Why Do We Need Silent Drones?

2025-09-02