What Are Commercial Drone Battery Connector Types?

In the realm of commercial drones, battery performance is critical—not only for maximizing flight time and payload capacity but also for ensuring safety, especially during high-current applications. A vital yet often overlooked component is the battery connector. The correct connector ensures optimal power delivery, reduces electrical resistance, and improves durability. This guide explores common commercial drone battery connector types, their features, and how to select the best option for your needs.

Common Commercial Drone Battery Connector Types

Commercial drones rely on a variety of battery connectors, each designed to meet specific current, voltage, and environmental demands. The most prevalent connectors in the industry include:

●XT Series (XT60, XT90): Widely used for their balance of size, current capacity, and ease of use. The XT90, in particular, is popular for high-power applications.

●AS Series (AS150, AS150U): Heavy-duty connectors designed for high-current, high-voltage drones, often seen in agricultural and industrial UAVs.

●EC Series (EC5, EC8): Known for high current ratings and secure connections, commonly used in mid-to-large-sized drones.

●Molex Connectors: Widely used in electronics, including drone power systems, with various pin configurations.

●ACES Connectors: Specialized connectors designed for specific drone battery applications.

●PDC1810F0002 Connector: A proprietary connector used in some industrial drone batteries for plug-and-play ease.

Each connector type has unique characteristics, such as current-carrying capacity, size, weight, and ease of connection, making them suitable for different drone applications. Below, we explore the specified connectors in detail.

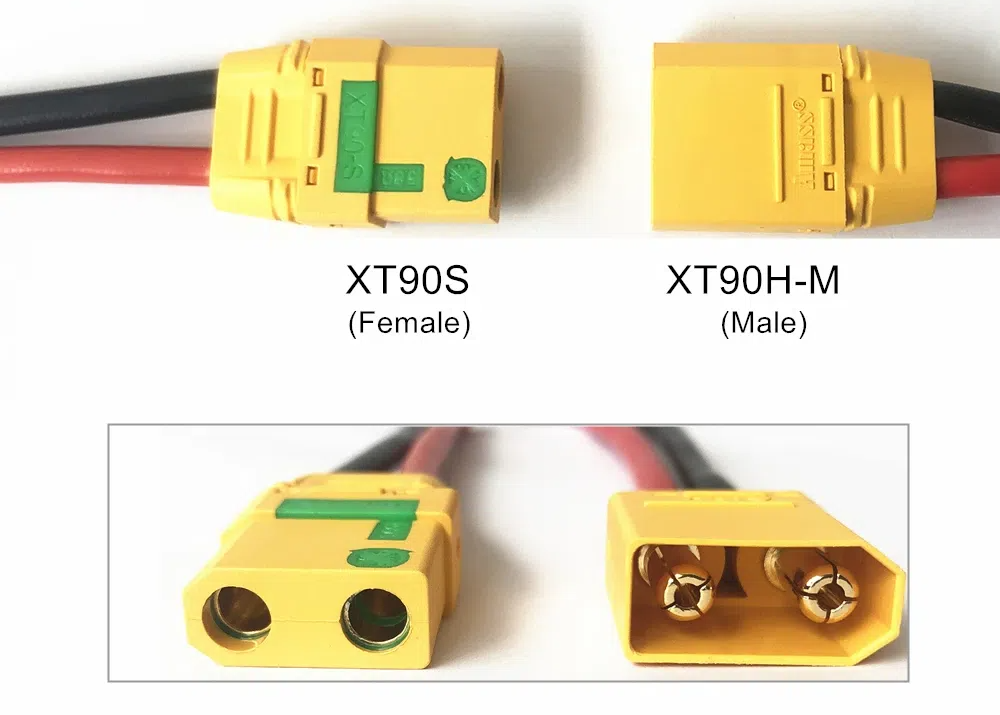

What are XT90S, XT90-S, and XT90S-F Connectors?

The XT90S is an enhanced version of the XT90 connector, manufactured by Amass, designed for high-current applications in drones and other RC vehicles. It is celebrated for its anti-spark feature, which reduces the risk of electrical arcing when connecting high-voltage batteries, thereby extending connector lifespan and enhancing safety.

●XT90-S: This is a variant of the XT90S, often used interchangeably in product descriptions. The “S” typically denotes the anti-spark feature, but some manufacturers label it as XT90-S to differentiate from older XT90 models without this technology. Specifications remain largely identical to the XT90S.

●XT90S-F: The “F” stands for “Female,” referring to the female plug of the XT90S connector. It is typically paired with the male XT90S (or XT90S-M) and used on the battery or charger side to ensure a secure, polarized connection. The female connector’s design prevents accidental polarity reversal, a critical safety feature.

Key Features:

Current Rating: Rated for 90A continuous, with a peak of up to 120A.

●Anti-Spark Technology: Incorporates a resistor in the connector to minimize sparking during connection, ideal for high-voltage LiPo batteries (6S to 12S).

●Material: Gold-plated contacts for low resistance and nylon housing for durability.

●Applications: Used in high-performance drones, such as those for cinematography, delivery, or racing, where high current draw is common.

What are AS150, AS150-F, AS150U, and AS150U-F Connectors?

The AS series connectors are designed for even higher current applications, often found in larger industrial drones.

●AS150: A heavy-duty connector utilizing 7mm gold-plated bullet connectors, capable of handling continuous currents around 150A. They often feature a screw-on shroud for added security and insulation. Some AS150 versions incorporate anti-spark technology, where one of the bullet pins is shorter and connects via a resistor first, similar to the XT90S.

●AS150-F: This refers to the female version of the AS150 connector. It is designed to mate with the AS150 male connector and shares the same high-current capabilities and 7mm bullet contacts.

●AS150U: This is an evolution of the AS150, often featuring an enhanced design for easier handling and potentially improved anti-spark capabilities. A key feature of some AS150U connectors is the inclusion of additional smaller signal pins alongside the main power pins. These signal pins can be used for battery management system (BMS) communication, allowing smart batteries to relay information like temperature, voltage, and cell health to the drone or charger. Current ratings are typically similar to the AS150, around 70A to 75A rated, with instantaneous currents up to 140A-150A. They also usually have an anti-reverse insertion design.

●AS150U-F: This is the female counterpart of the AS150U connector, incorporating the same features, including the potential for signal pins and the robust power connection. It's designed to connect to the AS150U male connector.

Key Features of AS150/AS150U:

●Very high current handling (often 150A continuous or more for AS150, around 70-75A continuous for AS150U).

●Large 7mm gold-plated bullet contacts (for AS150 power lines).

●Often incorporates anti-spark technology.

●Robust housing, sometimes with screw-on shrouds.

What is a Molex Connector?

Molex is not a single connector but a family of connectors known for signal, balance lead, or low-current connections in battery packs and flight controllers.They come in multiple configurations, from low-power signal connectors to high-current power connectors.

In drones, Molex connectors are often used for power distribution and signal connections due to their reliability and availability. For example, the Mini-Fit Jr. series is common for motherboard and power supply connections and can handle significant current loads. Molex connectors are valued for their secure locking mechanisms and versatility in pin count and arrangement.

Key Features:

●Typically used for balance charging leads, BMS signal cables, or ESC signal interfaces.

●Can be customized in various pitches (e.g., 2.0mm, 2.54mm).

●Provides secure locking, polarization, and compact design.

●Applications: Balance connectors on smart LiPo batteries, telemetry, communication lines between components.

What is an ACES Connector?

ACES (Advanced Connector Engineering Systems) connectors are precision-grade, high-reliability connectors often seen in aerospace, medical, and industrial drone applications. They are less common than XT or AS series but are gaining traction in high-reliability drone applications. ACES connectors are a premium choice for drones operating in extreme conditions or requiring complex electrical systems. Their adoption is growing as drone technology advances.

Key Features:

●Compact yet robust with high mating cycles.

●Available in high-pin-count configurations for signal, data, and power.

●Engineered for high-vibration, high-temperature, and harsh environments, with IP-rated sealing for dust and water resistance.

●Known for EMI shielding and vibration resistance, ideal for UAVs in harsh environments.

●Applications: Surveillance drones, defense drones, and high-reliability UAS requiring data redundancy and signal integrity.

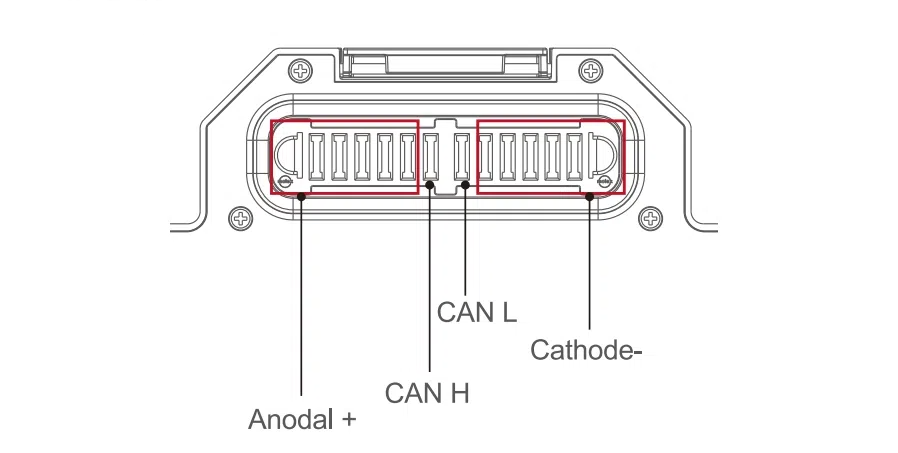

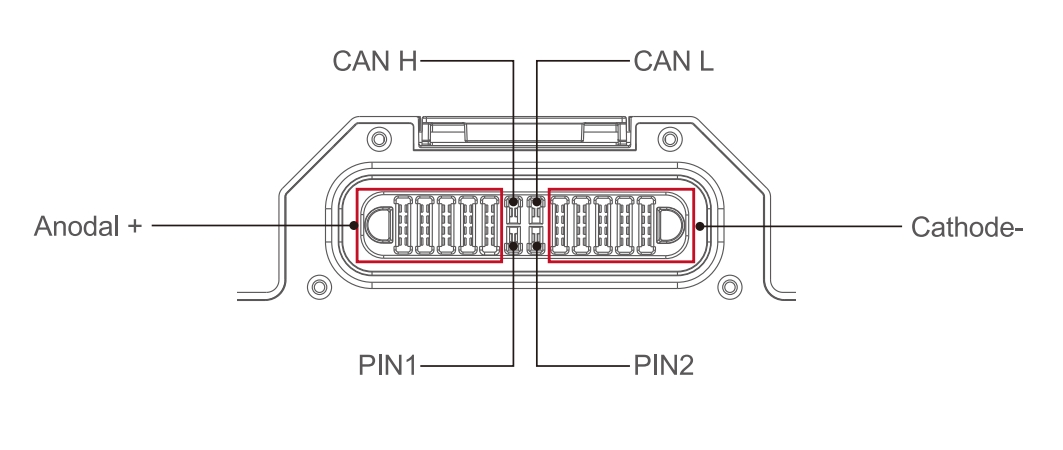

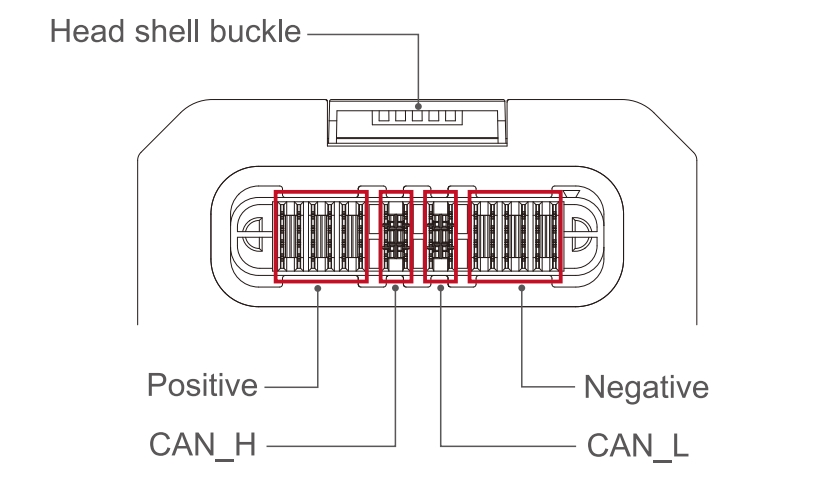

What is a PDC1810F0002 Connector?

The PDC1810F0002 is a specialized drone connector designed by Power Data Connectors (PDC) for smart battery integration.

Key Features:

●Compact form factor suitable for plug-and-play smart batteries.

●Combines high-current power pins with data pins for CAN/SMBus-based BMS communication.

●Designed for autonomous docking drones and battery swapping applications.

●Applications: Smart battery systems in enterprise-level drones, especially in autonomous BVLOS operations, where battery telemetry and plug-free operation are critical.

The Importance of a High-Quality Connector

Before exploring specific types, it's essential to understand why the choice of connector matters:

●Current Handling: Drones, especially larger commercial models, can draw significant current. A connector must be rated to handle this current without overheating, which could lead to failure or even fire.

●Secure Connection: Vibration and in-flight maneuvers can test the integrity of a connection. A robust connector ensures a steadfast link, preventing power interruptions.

●Durability: Connectors are subjected to repeated mating and de-mating cycles. High-quality materials and design contribute to a longer operational life.

●Low Resistance: A good connector minimizes electrical resistance, ensuring maximum power delivery and reducing heat build-up.

●Safety Features: Anti-spark technology and keyed designs prevent accidental short circuits and incorrect polarity connections, safeguarding both the equipment and personnel.

How to Choose a Drone Battery Connector?

Selecting the right battery connector for your drone involves considering several critical factors:

Battery Size and Current Requirements

Larger batteries with higher capacity and voltage require connectors rated for higher continuous and burst currents. For example, small micro drones may use JST or XT30 connectors, while larger drones benefit from XT60, XT90S, or AS150 connectors.

Wire Gauge Compatibility

The connector must match the wire gauge used. Thin wires with large connectors can cause mechanical stress on solder joints, while thick wires with small connectors may lead to overheating.

Safety Features

Anti-spark connectors like XT90S and AS150 reduce wear and risk during battery connection. MOSFET protection in smart connectors adds another layer of safety.

Ease of Use and Reliability

Connectors should be polarized to prevent reverse polarity, only connect one way, and withstand repeated connections without failure. Weather resistance and mechanical robustness are important for outdoor drone use.

Compatibility and Availability

Using common connectors increases the chance of having replacements or compatible batteries on hand during operations, reducing downtime.

Weight Considerations

While larger connectors handle more current, they add weight. For small drones, a balance between connector size, weight, and current capacity is essential.

Conclusion

In summary, commercial drone battery connectors range from widely used XT90S and AS150 series connectors to specialized Molex, ACES, and proprietary types like the PDC1810F0002. Understanding their specifications, safety features, and application contexts enables informed decisions that enhance drone performance and safety. Proper connector choice is a foundational aspect of drone power system design, impacting reliability and operational success. As a leading global manufacturer of commercial drone batteries, Grepow offers a wide range of high-performance LiPo UAV batteries and smart drone batteries, supporting configurations from 6S to 24S and capacities ranging from 10Ah to 84Ah. These batteries are equipped with a variety of high-current, industry-standard connectors—such as XT90S, AS150U, and custom smart interfaces—to meet the diverse demands of commercial drones across industries like agriculture, logistics, inspection, and public safety. If you have any questions or needs, please feel free to contact us at info@grepow.com.

Related Articles

-

How to Choose Battery for a Washing Drone?

2025-07-08 -

The Evolution and Challenges of Low-Altitude Economy

2025-07-01 -

Drone Batteries: A Comprehensive Guide

2025-06-23

Related products

-

Tattu Neo Series Smart Batteries For Industrial Drones

-

350Wh/kg Series Semi-Solid State High Energy Density Battery Pack

-

4.45V Ultra High Voltage Series Semi-Solid State Battery