Lithium-Sulfur Bettery vs Lithium-Ion Battery: What’s the Difference?

As the global demand for cleaner energy, electric vehicles, and high-performance devices continues to surge, the spotlight is increasingly turning to next-generation battery technologies. Among them, lithium-sulfur (Li-S) batteries have emerged as a promising alternative to the widely used lithium-ion (Li-ion) batteries. But how do these two technologies truly compare? Is Li-S the game-changer the industry has been waiting for, or is it still a distant dream? In this comprehensive guide, we’ll explore the key differences, underlying chemistry, performance metrics, challenges, and future outlook for both Li-S and Li-ion batteries, helping you understand which battery might lead the energy revolution.

What Are Lithium-Sulfur Batteries?

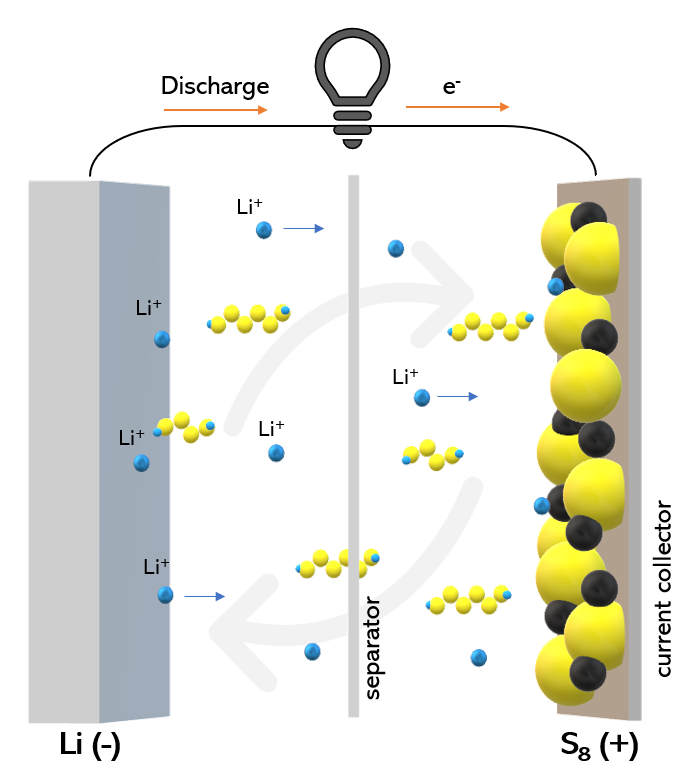

Lithium-sulfur batteries are a type of lithium-metal battery that utilize sulfur as the cathode material and metallic lithium as the anode. Unlike traditional lithium-ion batteries that rely on intercalation compounds (e.g., lithium cobalt oxide or lithium iron phosphate), Li-S batteries use elemental sulfur—an abundant and low-cost material. During discharge, lithium ions migrate from the anode to the cathode, where sulfur reacts with them to form lithium sulfides (Li₂S). Upon charging, this process reverses.

Is the Lithium-Sulfur Battery the Only Lithium-Metal Battery?

No, lithium-sulfur batteries are not the only type of lithium-metal battery. Lithium-metal batteries are a broad category that use metallic lithium as the anode, paired with various cathode materials. Other examples include:

●Lithium-air (Li-air) batteries: These use oxygen from the air as the cathode material, offering theoretical energy densities even higher than Li-S. However, they face significant challenges, such as poor cycle life and sensitivity to moisture.

●Lithium-metal batteries with intercalation cathodes: These pair a lithium-metal anode with traditional Li-ion cathodes (e.g., lithium cobalt oxide or lithium iron phosphate), aiming to improve energy density over conventional Li-ion batteries.

●Solid-state lithium-metal batteries: These use a solid electrolyte and can incorporate various cathodes, including sulfur or oxides, to enhance safety and stability.

Li-S batteries are one of several lithium-metal battery technologies, distinguished by their sulfur cathode and high theoretical energy density. What sets all lithium-metal batteries apart from Li-ion is the use of pure lithium metal as the anode, rather than graphite. This allows for significantly higher theoretical energy density but introduces challenges such as dendrite formation and safety risks.

How Do Lithium-Metal Batteries Work?

In lithium-metal batteries, ions move from the lithium anode to the cathode during discharge. In Li-S, sulfur undergoes reduction to form Li₂S, releasing energy. During charging, lithium is stripped back to the anode. This contrasts with Li-ion batteries, where lithium ions intercalate (embed) into graphite anodes and metal oxide cathodes (e.g., LiCoO₂), avoiding metallic lithium’s reactivity.The lithium metal anode provides a high theoretical capacity and low electrochemical potential, enabling high energy density. However, lithium metal’s high reactivity leads to challenges such as dendrite formation, which can cause short circuits and safety risks.

Lithium-sulfur battery vs Lithium-ion battery: what's the difference?

While both are lithium-based rechargeable batteries, Li-S and Li-ion batteries have several crucial differences:

Feature | Lithium-Sulfur (Li-S) | Lithium-Ion (Li-ion) |

Anode | Lithium metal | Graphite |

Cathode | Sulfur | Metal oxides (e.g., LiCoO₂, NMC) |

Energy Density | Theoretical: ~2,500 Wh/kg; Practical: ~500 Wh/kg | Moderate to high (typically 150-250 Wh/kg, advanced up to ~350 Wh/kg) |

Cycle Life | 100–500 cycles (current) | 1000–3000 cycles |

Cost of Materials | Low (sulfur is abundant) | High (cobalt, nickel are expensive) |

Environmental Impact | Lower (no heavy metals) | Higher (uses cobalt, nickel) |

Safety | Improved with solid electrolytes; risk from lithium metal | Relatively safe; mature technology |

Commercial Availability | Emerging, R&D stage | Mass-produced and widely used |

What Is the Lifespan of a Lithium-Sulfur Battery?

Li-S batteries typically last for about 300 to 500 charge-discharge cycles. This is a significant drawback compared to Li-ion batteries, which can exceed 1000 cycles in many applications. Their shorter lifespan compared to Li-ion batteries is mainly due to the "polysulfide shuttle effect," where intermediate polysulfide compounds dissolve into the electrolyte and migrate between electrodes, causing active material loss and capacity fade. Volume expansion and mechanical degradation also contribute to limited cycle life.

What Are the Advantages of Li-S Batteries?

Lithium-sulfur batteries offer several compelling advantages that drive the intense research and development efforts:

●High Energy Density: The theoretical energy density of Li-S is up to 500 Wh/kg, more than double that of Li-ion.

●Low Cost: Sulfur is abundant and inexpensive, unlike cobalt and nickel used in Li-ion.

●Lightweight: Sulfur and lithium are both low atomic weight elements, resulting in lighter batteries.

●Environmental Benefits: Sulfur is non-toxic, and Li-S batteries avoid heavy metals, reducing the environmental impact of mining and disposal.

●Scalability: With proper advancements, Li-S could be easier to scale than some solid-state designs.

What Is the Problem with Lithium-Sulfur Batteries?

Despite the promise, Li-S batteries face significant challenges:

●Short Lifespan: Polysulfide shuttle effect leads to loss of active material and poor cycle life.

●Poor Conductivity: Sulfur insulates, requiring conductive additives.

●Low Coulombic Efficiency: Inefficient lithium utilization due to side reactions and self-discharge.

●Dendrite Formation: Lithium metal anodes can grow dendrites, risking short circuits and fires.

●Volume Expansion: Sulfur expands significantly during cycling, leading to mechanical instability.

●Electrolyte Compatibility: Liquid electrolytes often react with lithium metal or dissolve polysulfides, necessitating specialized formulations or solid-state alternatives.

Are Lithium-Sulfur Batteries Safe?

Li-S batteries have both safety advantages and challenges compared to Li-ion batteries:

Safety Advantages:

●Lower Risk of Thermal Runaway: Sulfur cathodes are less prone to exothermic reactions than metal oxide cathodes, reducing the risk of fires or explosions.

●Non-Toxic Materials: Sulfur is non-toxic, unlike cobalt or nickel, making Li-S batteries safer for disposal and recycling.

Safety Challenges:

●Lithium Dendrites: Dendrite growth in lithium-metal anodes can cause short circuits, potentially leading to thermal runaway or fires.

●Electrolyte Flammability: Many Li-S batteries use flammable liquid electrolytes, posing risks if the battery is damaged.

●Polysulfide Reactions: Uncontrolled polysulfide migration can lead to chemical instability, though this is less hazardous than Li-ion thermal runaway.

To improve safety, researchers are exploring solid-state electrolytes, which eliminate flammable liquids and reduce dendrite formation. With these advancements, Li-S batteries could become as safe as or safer than Li-ion batteries.

Is Li-S Better Than Lithium-Ion?

Context matters. Li-S excels in energy density and weight, making it ideal for aerospace or EVs where range is critical. However, Li-ion’s maturity, longevity, and reliability keep it dominant for consumer electronics. Until Li-S overcomes its lifespan and safety hurdles, Li-ion remains the workhorse.

Are Lithium-Sulfur Batteries the Future?

Possibly. Companies like Oxis Energy and Sion Power are advancing prototypes, targeting EVs and aviation. NASA has tested Li-S for Mars rovers. Success hinges on solving the polysulfide shuttle and dendrite issues. If scalable solutions emerge, Li-S could displace Li-ion in niche markets by 2030.

What Is the Future of Lithium-Metal Batteries?

Lithium-metal batteries, including Li-S, Li-air, and solid-state variants, represent the next frontier in battery technology. Their future hinges on overcoming current limitations and leveraging their high energy density. Key trends and developments include:

●Solid-State Electrolytes: Replacing liquid electrolytes with solid alternatives (e.g., ceramics, polymers) could eliminate dendrite growth, improve safety, and extend cycle life. Solid-state lithium-metal batteries are a major focus for companies like QuantumScape and Solid Power.

A ●dvanced Anode Protection: Coatings, artificial SEI (solid-electrolyte interphase) layers, and 3D-structured anodes are being developed to stabilize lithium-metal anodes.

●Cathode Innovations: For Li-S, nanostructured sulfur-carbon composites and catalysts are improving conductivity and reducing polysulfide shuttling. For other lithium-metal batteries, high-capacity cathodes like nickel-rich oxides are being explored.

●Scalable Manufacturing: Streamlining production processes for lithium-metal batteries will be critical to compete with Li-ion’s established supply chain.

Conclusion

While lithium-ion batteries continue to dominate the market with their balance of energy, safety, and reliability, lithium-sulfur batteries represent a bold leap forward. With their higher energy density, lower cost, and eco-friendliness, they could redefine what's possible in electric mobility and renewable storage—if researchers can overcome their current limitations. As a global leading lithium-ion battery manufacturer, Grepow is now delivering semi-solid-state batteries boasting an impressive energy density of up to 350 Wh/kg. This significant advancement effectively tackles the limitations of lower energy density often associated with conventional lithium-ion batteries, making them an ideal power solution for cutting-edge applications such as drones and robotics. If you have any questions or needs, please feel free to contact us at info@grepow.com.

Related Articles

-

Why Do We Need Silent Drones?

2025-09-02 -

What is an Open-Source Drone?

2025-08-29 -

Top 10 Cargo Drones of 2025

2025-08-28

Related products

-

330Wh/kg Series Semi-Solid State High Energy Density Battery Pack

-

350Wh/kg Series Semi-Solid State High Energy Density Battery Pack

-

4.45V Ultra High Voltage Series Semi-Solid State Battery