Diaphragm - Internal materials that drone battery cannot be ignored

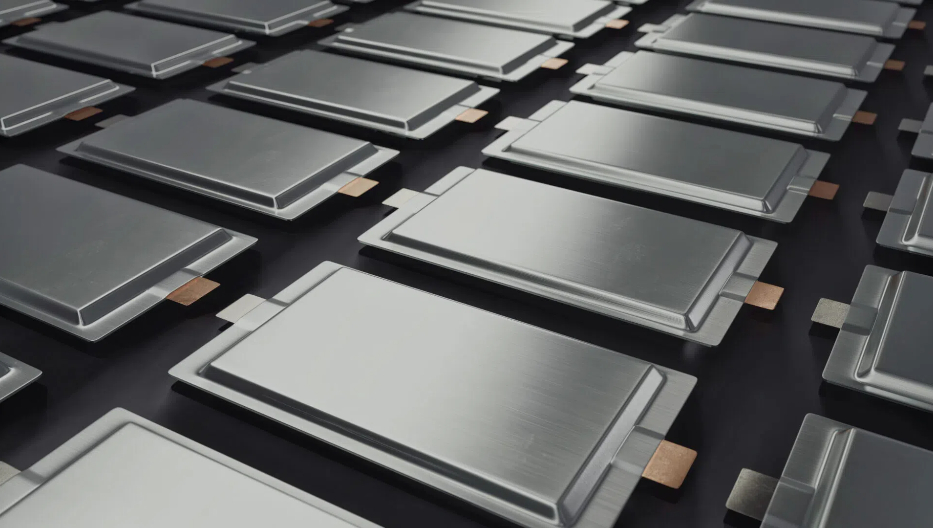

The long life and high rate of the drone battery have an important relationship with the diaphragm. As an important component of a drone battery, diaphragm is of great significance to block electrons by preventing short circuits and ensuring that internal ions can operate efficiently, steadily and safely through the batteries. Although the diaphragm itself does not have any electrochemical reaction, but its structure and performance affect the interface structure and internal resistance of the battery, and thus affect the overall capacity of the battery, charge and discharge current density, cycle performance and safety. Therefore, through the analysis and testing and regulation of the performance parameters of the lithium battery diaphragm, the comprehensive performance of the battery can be improved effectively.

Key performance indicators of the diaphragm

According to the U.S. Advanced Battery Alliance (USABC) for lithium-ion battery diaphragm performance parameters, battery diaphragm performance can be roughly divided into physical and chemical properties, mechanical properties, thermal properties and electrochemical properties of four aspects. Among them, the physical and chemical characteristics include thickness, porosity, average aperture size and aperture distribution, breathability, twists and turns, wetting, suction rate, chemical stability of 8 parameters. The mechanical properties mainly include the three parameters of puncture strength, mixed puncture strength and tensile strength. The thermal performance includes the thermal closing temperature, the melting fracture temperature and the heat shrinkage. Electrochemical properties include linear volt scanning test (LSV), electrochemical impedance spectrum test (EIS), cycle performance (CP), ion conductivity, and Mac-Mullin values.

The important role of diaphragm

First, the diaphragm has electronic insulation, to ensure the organic isolation of the positive and negative poles, reducing the probability of self-ignition of the drone battery. Second, because the diaphragm has a certain aperture, lithium ionhasitus has a good penetration, which can be a good guarantee of low resistance and high ion conductivity. Third, the diaphragm has sufficient chemical stability, a certain degree of moisture resistance and corrosion resistance. The importance of increasing the life of the battery in the use of drone batteries is clearly appreciated. Fourth, the diaphragm material has excellent thermal stability, in the temperature is particularly high can automatically shut down the power supply. To some extent, it's very protective. Fifth, the diaphragm of the drone battery must have sufficient mechanical properties, including puncture strength, tensile strength, ultra-thin thickness and so on. Finally, the diaphragm must be well-soaked to the electrolyte, maintaining sufficient suction capacity and ion conductivity.

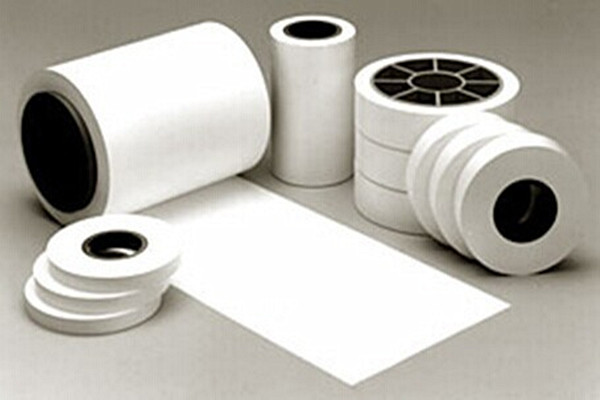

Specific classification of diaphragm

Due to the different types of batteries, the corresponding diaphragms are also different. I'm here to popularize the classification of lithium batteries. Lithium battery diaphragm is divided into five main, multi-layer diaphragm, organic composite film, inorganic composite film, ceramic coating diaphragm, new diaphragm. Multi-layer diaphragm contains PP/PE/PP three layers of composite film in turn pasted together. Because of this feature, multi-layer diaphragm combines low closed hole temperature with good membrane temperature, making it the preferred target for batteries used at low temperatures. The important difference between organic compound film and inorganic compound film is suitable for electromechanical solution and no electromechanical solution. Both use PEG diaphragms of inorganic nanomaterials to enhance humidity. All have good heat resistance and low internal resistance characteristics. Ceramic coating diaphragm is based on PP, PE or multi-layer composite diaphragm, the surface coated with a layer of nano-grade aluminum trioxide material. After special process treatment, and the substrate bonded tightly. Significantly improve the high temperature resistance and safety of lithium-ion batteries. Ceramic-coated diaphragms are ideal for power batteries. The technical characteristics of the new diaphragm are more complex, many are still under development, but have another special feature - the high melting point of the diaphragm. At present, the drone battery on the market mainly uses lithium battery stacking technology, electrolyte is an organic solvent system, generally using high-strength thin film flower polyolefin porous film. According to the flight characteristics of the drone, the battery mainly uses a diaphragm with good heat resistance and low internal resistance.

Industry standard for diaphragms

As the diaphragm industry still lacks a set of complete testing and evaluation standards specifically for lithium-ion battery diaphragms, each diaphragm manufacturer uses its own corporate standards for evaluation of its products. This not only to the performance of different diaphragms between the inconvenience, but also lead to uneven product quality, affecting the overall quality of the domestic diaphragm market. Lithium battery diaphragm low-end products are highly competitive, high-end products are the direction of development.

With the increasing demand for lithium batteries in safety, load density and so on, the demand for high-end diaphragm products is also increasing. Although the global diaphragm market development is different, but the high-end diaphragm market profitability is still well guaranteed. Manufacturers with high-end product production capacity are much higher than the national average, and have entered the supply chain system of first-line power battery manufacturers at home and abroad. Therefore, high-end products will be the future development direction of the drone battery diaphragm market.

Grepow has more than 20 years of experience in the battery manufacturing industry, with a group of excellent battery manufacturing experts, deep understanding of different diaphragm product quality. Buy the best diaphragm models and materials for drone batteries by testing performance yourself. In battery solutions, Grepow became one of the world's largest battery manufacturers. If you are interested in our drone battery, please don't hesitate to contact us at any time! Keep an eye on Grepow’s official blog, and we’ll regularly update industry-related articles to keep you up-to-date on the battery industry. Email: info@grepow.com

Grepow Website: https://www.grepow.com/

Grepow Blog: https://www.grepow.com/blog.html

Related Articles

-

The Ultimate Guide to Grepow Jump Starter

2025-03-27 -

How to Choose Lithium Batteries for Cold Weather?

2024-09-19 -

Next-Generation eVTOL Battery Technology

2024-08-22

Related products

-

Tattu Plus 6S 10000mAh 22.2V 25C Lipo Smart Drone Battery

-

Tattu Pro 14S Lipo 22000mAh 51.8V Smart UAV Drone Battery Pack

-

Tattu Plus 1.0 Compact 12S 16000mAh 44.4V 15C Lipo Smart Drone Battery