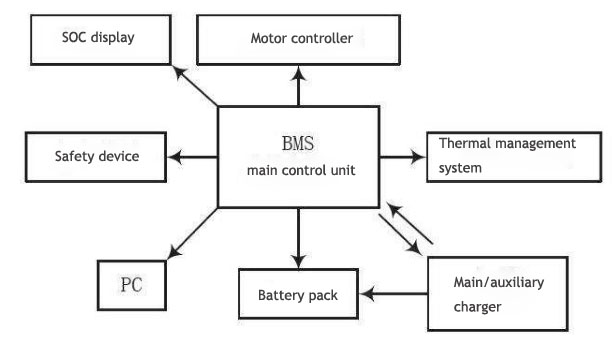

Battery Management System Structure

What is Battery Management System?

The battery management system is mainly composed of a charging module, a data acquisition module (including voltage, current, temperature data acquisition), an equalization module, a power calculation module, a data display module, and a storage communication module, and mainly manages and protects the use of the battery pack.

What can Battery Management System do?

The battery management system (BMS) involves technologies such as microcomputer technology and detection. It implements dynamic monitoring of the operating status of battery cells and battery packs, accurately calculates the remaining battery capacity, and protects the battery from charge and discharge, working condition so that BMS helps uesers reduce operating costs and increase service life as well.

What consists of a Battery BMS?

The battery management system structure adopts a modular and distributed design.

The system includes a 2-level control structure, namely a local measurement module and a central processing module. Among them, the main function of the central processing module is to use the RS232 interface to communicate with the host computer, and communicate with the local measurement module in the form of CAN bus network;

The main function of the local measurement module is data acquisition (mainly data acquisition of temperature, current, and voltage), charge and discharge control, power measurement, single battery equalization and communication with the central processing module using CAN bus technology. The data acquisition module in the battery management system is responsible for collecting various state parameters of the battery, such as current, voltage and temperature;

The charging control module performs automatic charging according to three stages of pre-charging, constant-current charging and constant-voltage charging, and according to the collected data. The charging and discharging process is controlled;

The equalization module equalizes and charges a single battery through a 15W switching power supply at an appropriate time, so that the battery in the battery pack is more balanced and consistent;

The power estimating unit mainly analyzes the collected state parameters according to the research. The electric quantity estimation algorithm obtained by the experiment estimates the current battery power;

The data display unit adopts a graphic liquid crystal display to display the battery voltage, charge and discharge current, remaining power, battery temperature and charging time;

Storage communication is the unit to store the charge and discharge information (voltage, current, charge and discharge time, etc.) through the memory chip timing, and can communicate with the computer through the serial port to display the charge and discharge information on the computer.

If you are interested in our products, please don't hesitate to contact us at any time! Email: info@grepow.comGrepow Website: https://www.grepow.com/

Related Articles

-

The Ultimate Guide to Grepow Jump Starter

2025-03-27 -

How to Choose Lithium Batteries for Cold Weather?

2024-09-19 -

Next-Generation eVTOL Battery Technology

2024-08-22