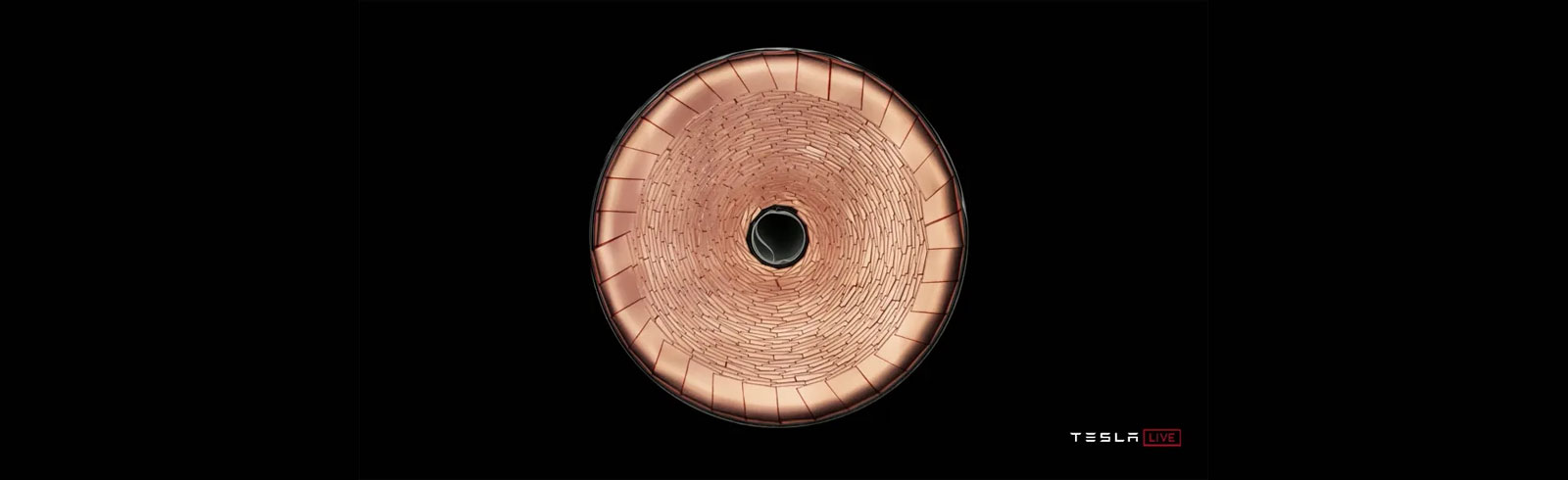

Tesla's new 4680 cylindrical battery

On September 22, 2020 on Battery Day, Tesla founder Elon Musk previewed the possibility of a fully automatic Tesla vehicle at $25,000 (£19,600) in about three years' time; this would make him one step closer to meeting his dream of building an affordable electric vehicle.

Further announced was that Tesla would begin producing their own batteries while continuing to purchase batteries from Panasonic and LG Chem.

Musk also anticipates that Tesla will play a vital role in the three components of a sustainable energy future: sustainable energy generation, storage and electric vehicles.

But most importantly, Musk announced a technology that he claimed will make Tesla batteries cheaper and more powerful: the new 4680. The battery will have fives times the energy and six times the power of a Panasonic 2170 that is currently used in the company’s Model 3 and Y. With a diameter of 46mm and a length of 80mm, this cylindrical battery has a new tabless design, a challenging and innovative move that will reduce the cost and increase the efficiency in production.

In fact, Andrew Baglino, SVP of Powertrain and Energy Engineering at Tesla, said that changing the modified shape and size of the battery could reduce the cost per kWh by 14%. Combined with the capacity and factory efficiency levels of the 4680 battery, this will result in a 32% reduction in cost per kWh.

The new battery cells are a major breakthrough for Tesla as it works to produce low-cost, long-range electric vehicles with a 16% increase in driving range--although the technology could take years to come to fruition, according to Musk.

Tesla’s goal is to reach “Terawatt-hour” (TWh) scale battery production (To understand the scale of what TWh means, know that tera equates to a trillion, which is 1,000 times of giga). By 2022, Tesla's pilot plant will be expected to produce 100 GWh per year from 4680 batteries, and, by 2030, the company will have a capacity of 3 TWh.

Tesla has further announced that it will move to structural battery packs instead of its usual “skateboard” design. A mid-mounted housing will hold the battery cells, which will eventually become part of the vehicle body. To achieve this, a special high-strength aluminum alloy was created for the casing; it is less prone to deformation and able to remain lightweight (10% less) and thus extend the driving range of the vehicle.

To streamline the supply chain, Tesla has taken steps to cut costs in the manufacturing and mining process. The company plans to build a new cathode plant in North America that will aim to eliminate the solvent step in the cathode process, thus saving time and resources in cathode production. Musk said that eliminating this step could reduce the company's ecological footprint by 10-fold.

There are clearly many improvements and plans to look forward to from Tesla in the coming year. Since Battery Day, there has only been increased attention and curiosity as to what Tesla has in store.

Related Articles

-

Why Do We Need Silent Drones?

2025-09-02 -

What is an Open-Source Drone?

2025-08-29 -

Top 10 Cargo Drones of 2025

2025-08-28