Discussion on the Drone Power Source

The main power source for drones is batteries. At present, the drones mainly use polymer lithium batteries with flexible packaging.The average flight time to power a drone is between 20 and 30 minutes.There are different reasons for the difference in lithium battery development technology. Most uav flight duration is less than 45 minutes. Because the weight of the uav design is very light, so it can not use heavy lithium battery capacity, the uav in the flight range of 10 minutes to 20 minutes, you have to change the lithium battery. There are other components of motivation that Grepow will discuss of the following.

The power of drone mainly refers to two components

The first is the Motor. The second is the Speed Controller, which controls the motor Speed. A long time ago, the early governor was realized by using the adjustable resistance dial controlled by the steering gear. This type is called the mechanical governor, which is now out of the historical stage. Now when we say governor, we refer to Electronic Speed Controller (ESC).

According to the drone power source broad categories, can be divided into brushed power and Brushless power. That is brushed Electronic Speed Controller with Brushless motor, and Brushless Electronic Speed Controller with a Brushless motor.

Brush motor and Brushless motor

The motors used in UAV are all inner rotor motors, that is, the motor shell is fixed and rotates on the inner circular rotor. The outer rotor is not discussed here, want to understand the outer rotor and the inner rotor, you can continue to follow Grepow website to understand.

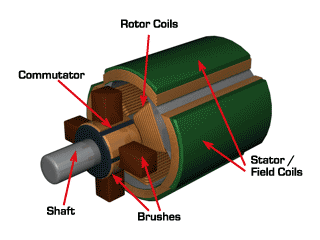

Brush motor: early motor, the magnet is fixed to the motor shell or base, as a stator. Then the coil windings are turned into rotors. The brushed motor used by UAV is generally wound in 3 groups. The figure below is the typical structure of the brushed motor.

It can be seen from the picture that the most basic components of the brushed motor include stator, rotor and carbon brushed. Therefore, the brushed motor is also called carbon brushed motor or carbon brushed motor. The carbon brushed contacts the copper head on the winding to allow the motor to rotate. However, due to the high-speed rotation, it will bring wear and tear of the carbon brushed, so the brushed motor needs to replace the carbon brushed after the carbon brushed is used up. The copper head would also wear out, so in the era of carbon brushed, racing motors needed to be polished to keep the copper head smooth, in addition to replacing the carbon brushed. After replacing the carbon brushed, it needs to be running-in to maximize the contact area between the carbon brushed and the copper head, so as to achieve the maximum current to improve the motor speed and torque.

Brushless motor: since the brushed motor has the above disadvantages, the Brushless motor came into being.

Brushless means winding the coil around the stator and then turning the magnet into a rotor, turning the magnet instead of the coil, so there is no consumable carbon brushed.

Now that the coil is fixed, how do you get the coil to produce a changing magnetic field? That's why Brushless requires 3 wires. The magnet rotor can be continuously driven to keep rotating by using Brushless electric regulation to generate a corresponding magnetic field by supplying power to the coil set correspondingly.

whether there are brushed motors or countless motors, the basic principle is to generate a magnetic field through the coil and then with a permanent magnet to drive the rotor rotation. A brushed is a permanent magnet used to make a stator and a coil used to make a rotor. Brushless coils are made into stators and permanent magnets into rounded rotors.

Brushed ESC and Brushless ESC

There is brushed Electronic Speed Controller, after talking about the brushed motor, naturally mentioned to have brushed Electronic Speed Controller, there is brushed Electronic Speed Controller is used to control the speed of brushed motor equipment.

There are only four wires in the brushed, and the two are the input power terminals and are connected to the positive and negative poles. The other two are output terminals that control the speed of the motor and are connected to the two electrodes of the motor. The rotation speed and the positive and negative control can be realized by changing the current/ voltage and the conduction direction.

Before the top competition level brushed, electric regulation is not with the reverse, so there is only 3 wire pole, connected to the motor positive pole and the battery positive pole is the same wire pole.

Brushless Electronic Speed Controller and brushed Electronic Speed Controller is the same principle, Brushless motor to work, it is necessary to a Brushless Electronic Speed Controller. Brushless electric input is the same as 2 lines, positive and negative power supply. However, Brushless electric output requires 3 wires. The principle in the above introduction to the Brushless motor when we said that is to rely on 3 wires to constantly change the magnetic field to drive the rotor rotation.

By means of the principle, we know that the Brushless motor must be used by the Brushless motor. And the brushed motor needs to be driven by a brushed. But some of the brushless Electronic Speed Controller can be used to rewrite the built-in program to allow the output of the 3-wire bridge to be ground to two to drive the brushed motor.

Related Articles

-

Powering Aerial Artistry: Grepow Battery Solutions Behind Drone Light Shows

2025-10-27 -

Powering the Future of Wearables: How Grepow's Patented Curved Battery is Revolutionizing the Smart Ring

2025-10-16 -

Grepow Battery Announces Manufacturing Agreement with Powerbanc Group

2025-09-30