How Is a LiPo Battery Manufactured?

Lithium polymer (LiPo) batteries, with their high energy density and flexible, slim form factor, have become the "heart" of modern electronics. From smartphones and drones to electric vehicles, the presence of LiPo batteries is ubiquitous. Yet, behind their seemingly simple exterior lies a series of intricate and interconnected manufacturing processes. This article delves into the core of LiPo battery production, breaking down 13 key steps from raw materials to the finished product, offering a glimpse into the secrets of this power-packed journey.

The LiPo battery manufacturing steps you're familiar with—slurry mixing, coating, calendering, slitting, stacking, welding, sealing, baking, electrolyte injection, formation, aging, capacity check, and grading—provide an accurate overview of the core processes. Below, we'll expand on each step and analyze its profound impact on the battery's final performance.

Phase I: Building the Electrodes (Slurry Mixing -> Coating -> Calendering -> Slitting)

The performance foundation of a LiPo battery begins with the meticulous fabrication of its positive and negative electrodes. The goal of this phase is to produce electrode sheets with uniform thickness and consistent active material distribution.

1. Slurry Mixing

Detailed Description:

●Slurry mixing is the starting point of battery manufacturing, much like preparing batter for a cake. This process, conducted in a vacuum mixer, involves combining active materials (e.g., lithium cobalt oxide or lithium manganese oxide for the cathode, graphite for the anode), conductive agents (e.g., carbon black), and binders (e.g., PVDF) in precise proportions with a solvent (NMP or a water-based solvent) to form a uniform slurry with a specific viscosity.

Production Essentials:

●Precise Proportions: The ratio of active materials, conductive agents, and binders directly determines the electrochemical and mechanical properties of the electrode.

●Uniform Dispersion: The uniformity of the slurry is critical. Particle agglomeration can lead to uneven coating, affecting the battery's capacity and lifespan.

●Viscosity Control: The slurry's viscosity must be suitable for the subsequent coating process; if it's too high or too low, it will cause difficulties or defects in coating.

Impact on Performance:

●Capacity & Energy Density: A higher proportion of active material leads to greater theoretical capacity and energy density.

●Internal Resistance & Rate Capability: The uniform dispersion of the conductive agent effectively lowers the electrode's internal resistance, enhancing the battery's high-current discharge (rate) performance.

●Cycle Life: The quality and distribution of the binder influence the structural stability of the electrode materials during repeated charge and discharge cycles, directly impacting the battery's cycle life.

2. Coating

Detailed Description:

●The prepared slurry is uniformly coated onto a metal current collector using a precision coater. Cathode slurry is applied to aluminum foil, while anode slurry is applied to copper foil.

Production Essentials:

●Thickness Consistency: The coating thickness must be highly consistent at the micron level, which is crucial for ensuring uniform battery performance.

●Surface Quality: The coating surface should be smooth, free from scratches, particles, bubbles, or other defects.

●Drying Control: After coating, the wet electrode sheet needs to be dried in an oven to remove the solvent. The drying temperature and speed must be strictly controlled to prevent the coating from cracking or peeling from the current collector.

Impact on Performance:

●Consistency: The uniformity of the electrode coating directly determines the uniformity of the current distribution within the cell, which in turn affects overall battery performance and lifespan.

●Safety: Coating defects, such as particles or scratches, can puncture the separator, leading to an internal short circuit and seriously compromising battery safety.

3. Calendering / Rolling Press

Detailed Description:

●The dried electrode sheets are passed through a pair of high-precision rollers to compact the electrode coating, increasing the active material's packing density.

Production Essentials:

●Pressure and Gap Control: The pressure and gap of the rollers must be precisely set to achieve the target thickness and packing density. Excessive pressure can crush the electrode material particles, while insufficient pressure results in poor compaction.

●Surface Smoothness: The roller surfaces must be extremely smooth to ensure a flat electrode surface after rolling.

Impact on Performance:

●Energy Density: Increasing the packing density means more active material can be packed into a limited space, significantly boosting the battery's volumetric energy density.

●Internal Resistance: Proper compaction brings active material particles into closer contact, lowering the electrode's internal resistance.

●Electrolyte Wettability: A higher packing density isn't always better; excessively high density can reduce porosity, affecting subsequent electrolyte wetting and, counterintuitively, increasing internal resistance and impacting rate performance.

4. Slitting / Notching

Detailed Description:

●The full roll of electrode sheet is cut into smaller rolls of the required width, and tabs for welding are stamped out using a precision cutter or laser cutting, based on the battery's design dimensions.

Production Essentials:

●Dimensional Accuracy: The cutting dimensions must be precise to ensure proper alignment during stacking and sealing.

●Burr Control: The cut edges must be smooth and free of metal burrs. Burrs are a major hidden danger that can cause internal short circuits.

●Clean Environment: This process must be carried out in a cleanroom to prevent dust contamination of the electrodes.

Impact on Performance:

●Safety: Burrs are a critical defect to avoid in LiPo battery manufacturing. They can easily puncture the separator, causing direct contact between the positive and negative electrodes, and leading to thermal runaway.

Phase II: Assembling the Cell (Stacking -> Welding -> Pouch Forming & Sealing)

After obtaining the qualified electrode sheets, the process moves to assembling them into a cell.

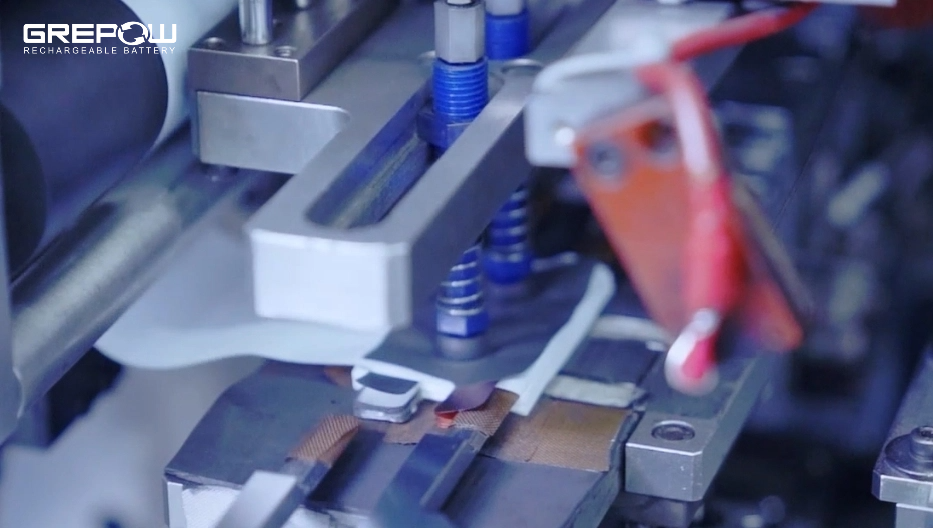

5. Stacking

Detailed Description:

●This is a typical process that differentiates LiPo batteries from cylindrical lithium-ion batteries. Workers or automated equipment stack positive electrodes, separators, negative electrodes, and separators in a layered "sandwich" structure. The separator acts as an insulator, preventing short circuits between the positive and negative electrodes while allowing lithium ions to pass through.

Production Essentials:

●Alignment Accuracy: The alignment between layers must be highly precise. The negative electrode is typically made slightly larger than the positive electrode to ensure it fully envelops the positive electrode, preventing the formation and deposition of lithium dendrites.

●Tension Control: The tension during stacking must be moderate to prevent the separator from being stretched or the electrode sheets from wrinkling.

Impact on Performance:

●Capacity & Internal Resistance: The neatness of the stacking affects the current density distribution inside the cell, which impacts the actual usable capacity and internal resistance.

●Cycle Life: Poor alignment can exacerbate edge effects, affecting the battery's cycle stability.

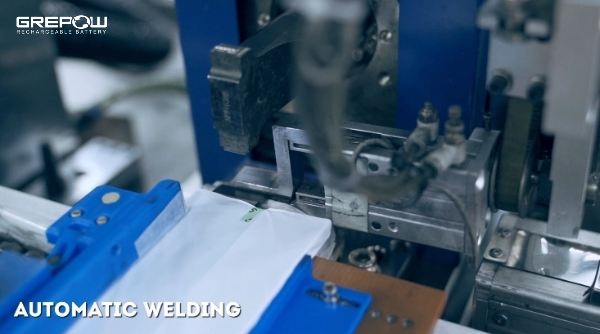

6. Welding

Detailed Description:

●All positive electrode tabs from the stacked cell are welded together to form the positive terminal, and all negative electrode tabs are welded together to form the negative terminal. Common welding methods include ultrasonic and laser welding.

Production Essentials:

●Weld Strength: Welds must be strong and reliable to withstand subsequent processing and vibrations during battery use.

●Weld Resistance: The resistance of the weld spots should be as low as possible; otherwise, it will contribute to the battery's internal resistance and affect performance.

●No Cold Welds or Over-Welds: Cold welds lead to poor contact and increased internal resistance; over-welds can damage the tabs or the cell.

Impact on Performance:

●Internal Resistance & Rate Performance: The quality of the welding directly affects the battery's internal resistance. Low-quality welds can significantly increase internal resistance, limiting the battery's high-current discharge capability and leading to increased heat generation.

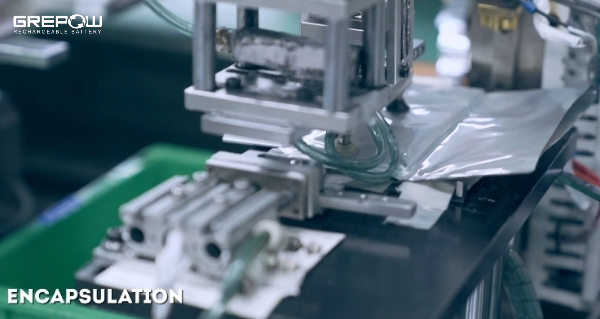

7. Pouch Forming & Sealing

Detailed Description:

●The welded cell tabs are placed inside a pre-formed aluminum-laminate pouch. The pouch is then sealed on the top and sides using a heat-sealing process, leaving one opening for later electrolyte injection.

Production Essentials:

●Hermetic Sealing: The seal must be completely airtight to prevent external air and moisture from entering the cell and to prevent electrolyte leakage.

●Pouch Dimensions: The aluminum-laminate pouch dimensions need to match the cell, ensuring the cell isn't squeezed while also avoiding excessive internal air space.

Impact on Performance:

●Safety and Life: A good seal is fundamental to maintaining a stable chemical environment inside the cell. Any leakage can cause the electrolyte to react with moisture in the air, creating harmful substances that severely affect the battery's lifespan and safety.

Phase III: Cell Activation & Testing (Baking -> Electrolyte Injection -> Formation -> Aging -> Capacity Check -> Grading)

After the bare cell is assembled, it must undergo a series of "activation" and "screening" processes before it can become a qualified LiPo battery.

8. Baking

Detailed Description:

●The sealed but un-injected cells are placed in a vacuum oven and baked for an extended period at a specific temperature.

Production Essentials:

●Vacuum Level and Temperature: The set vacuum level and temperature must be achieved to effectively remove residual moisture and solvents from inside the cell.

Impact on Performance:

●Performance & Life: Moisture is the "natural enemy" of lithium batteries. It reacts with lithium salts in the electrolyte to produce acidic substances like HF, which corrode the electrode materials, leading to capacity fade and increased internal resistance, severely shortening battery life.

9. Electrolyte Injection

Detailed Description:

●In a glove box or dry room with strictly controlled humidity, a precise amount of electrolyte is injected into the baked cell through the pre-sealed opening. The electrolyte is the medium for lithium ion transport.

Production Essentials:

●Injection Volume Precision: The volume of electrolyte must be precise; too much or too little will affect battery performance.

●Wetting Time: After injection, the cell needs to be left to stand for a period of time to allow the electrolyte to fully wet the electrodes and separator.

●Environmental Control: The entire process must be carried out in an extremely low-humidity environment.

Impact on Performance:

●Ionic Conductivity: The amount of electrolyte and the degree of wetting directly determine the internal ionic conductivity of the battery, thereby affecting internal resistance and rate performance.

10. Formation

Detailed Description:

●This is a crucial step in LiPo battery production. It involves the first charge and discharge of the electrolyte-injected battery. During the initial charge, the electrolyte reacts on the anode surface, forming a thin, dense passivation layer known as the Solid Electrolyte Interphase (SEI) film.

Production Essentials:

●Charge/Discharge Profile: The formation process typically uses small currents for multiple charge-discharge cycles. Parameters like current magnitude, charge cutoff voltage, and cycle count have a decisive impact on the quality of the SEI film.

●Degassing: A small amount of gas is produced during formation. This gas needs to be vented through a secondary sealing (degassing sealing) process, and then the cell is finally sealed.

Impact on Performance:

●Cycle Life and Safety: A stable and dense SEI film effectively prevents further decomposition of the electrolyte and solvent molecules from embedding in the anode. This is essential for improving the battery's cycle life and safety. A poor SEI film, however, can lead to rapid capacity fade and safety hazards.

11. Capacity Check

Detailed Description:

●The formed batteries undergo standard charge and discharge tests to precisely measure their initial capacity, internal resistance, voltage, and other key parameters.

Production Essentials:

●Uniform Test Standards: All batteries must be tested under the same conditions, such as identical charge/discharge currents, cutoff voltages, and ambient temperatures.

Impact on Performance:

●Quality Control: This is the first critical checkpoint to evaluate whether the batteries meet the design requirements. Non-conforming products are screened out.

12. Aging

Detailed Description:

●Aging is a period of rest during the battery production process. In this phase, internal chemical reactions (like SEI film formation) continue and stabilize. It's similar to letting a newly produced bottle of wine "breathe" to allow its flavors and quality to become more stable.

Production Essentials:

●Temperature and Time: The cells are left to rest at 30-45°C for 8-16 hours or longer to allow the internal chemical reactions to fully complete.

●Vacuum and State of Charge (SOC): Some processes involve a vacuum treatment to extract gas from the battery and prevent swelling. The SOC during aging is also precisely controlled.

Impact on Performance:

●Stable Performance: Aging stabilizes the battery's capacity and internal resistance, preparing it for precise subsequent testing.

●Extended Lifespan: A stable protective film (SEI film) improves the battery's cycle life.

●Ensured Safety: This step helps screen out defective batteries, reducing safety risks.

●Improved Consistency: It makes the performance of all batteries more uniform, which is convenient for sorting and grouping.

13. Grading

Detailed Description:

●Based on the results of the capacity check, batteries are sorted into different grades. This is typically done by slight differences in capacity, internal resistance, voltage, and other parameters, categorizing them into Grade A, Grade B, etc.

Production Essentials:

●Sorting Criteria: Clear sorting criteria must be established to ensure that batteries within the same batch and grade have highly consistent performance.

Impact on Performance:

●Battery Pack Performance: For battery packs that require multiple cells to be connected in series or parallel (e.g., electric vehicle battery packs), cell consistency is paramount. Using cells of the same grade with similar performance is essential for ensuring the overall performance, lifespan, and safety of the battery pack.

Conclusion

In conclusion, LiPo battery manufacturing is a systematic process where each step acts like a precise gear, interlocking tightly to collectively determine the final product's performance, lifespan, and safety. From the slurry proportions to the formation process, a lapse in any single detail can lead to a "miss by a millimeter, a mile by a consequence." It is this masterful control over these complex processes that enables LiPo batteries to provide the constant, powerful energy for our digital lives. As a global leading LiPo battery manufacturer, Grepow is the powerhouse behind industry-renowned brands: Tattu, dedicated to drone batteries; Gens ace, specialized in RC model battery solutions; and Lokithor, focused on high-performance jump starters. From industrial to consumer applications, from robotics to smart wearables, Grepow is committed to advancing LiPo battery technology—empowering innovation across every industry. If you have any questions or needs, please feel free to contact us at info@grepow.com.

Related Articles

-

Vatican Drone Show: Where Technology Meets Faith

2025-09-15 -

New Release: Tattu TA300 Multi-Channel Smart Charger for Drone Soccer

2025-09-12 -

How to Handle Battery Overheating Issues?

2025-08-12

Related products

-

Tattu 12S LiPo Drone Battery Series

-

Tattu Agricultural Drone Battery

-

Tattu 6S LiPo Drone Battery Series