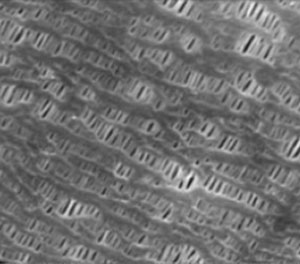

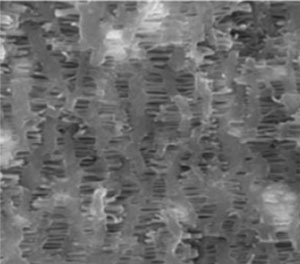

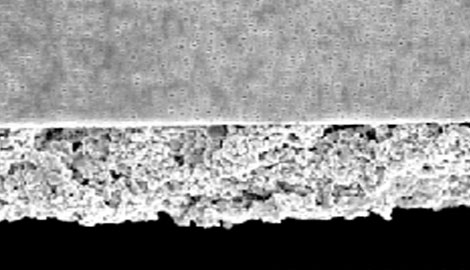

Diaphragm with a dense porous structure, which allows it to achieve a more uniform pore distribution which in turn can reduce internal resistance and improve discharge performance of our batteries.

Surface SEM image of Battery Diaphragm

Section SEM Portrait image of Battery Diaphragm

The surface-coated nano-ceramic battery separator has the advantages of high temperature resistance, high voltage resistance, high puncture and high liquid absorption, which can greatly improve the heat shrinkage of the diaphragm and improve the safety and reliability of the battery.

According to UL1642 heating for 30min (hot oven 130°C).

Cell opening, no fire, no explosion, weight loss ≤ 10%.

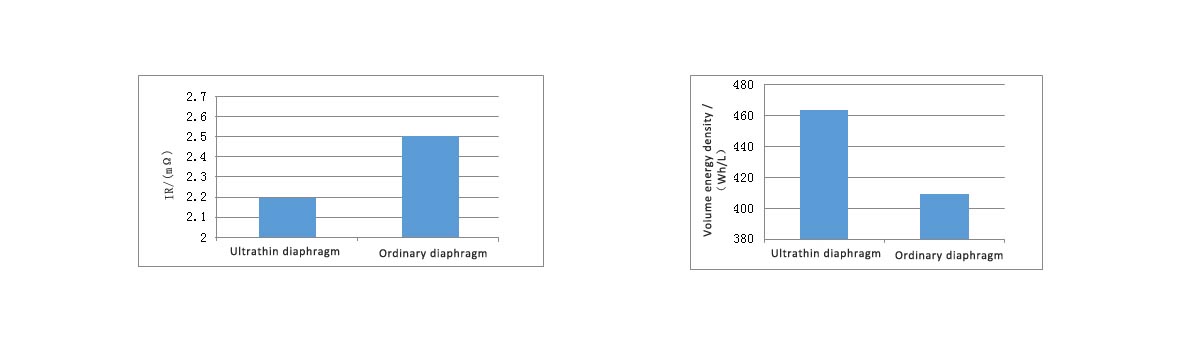

The 9um diaphragm reduces the internal resistance of the battery and increases the volumetric energy density of the battery.

| GRP5742085 | Diaphragm thickness | Capacity (mAh) | Internal Resistance (mΩ) | Cell Weightg(g) | Energy density (Wh/L) |

|---|---|---|---|---|---|

| Ultrathin diaphragm | 9μm | 2550 | 2.2 | 45.5 | 464 |

| Ordinary diaphragm | 12μm | 2550 | 2.5 | 42.5 | 409 |

Ultrathin vs Ordinary Diaphragm Comparison

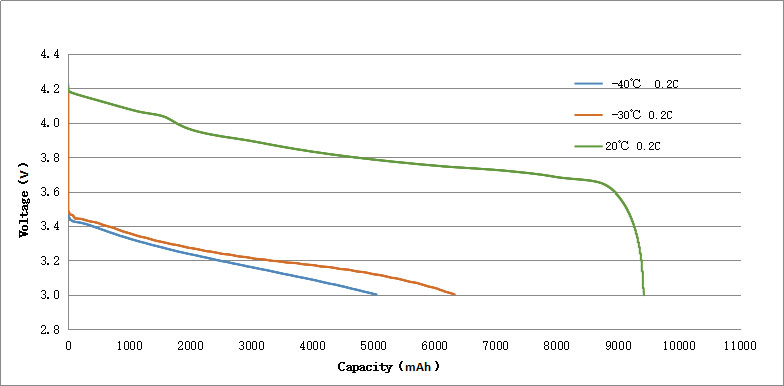

Comparison of different temperature discharge curves of low temperature batteries.

Discharge Curves at Different Temperatures

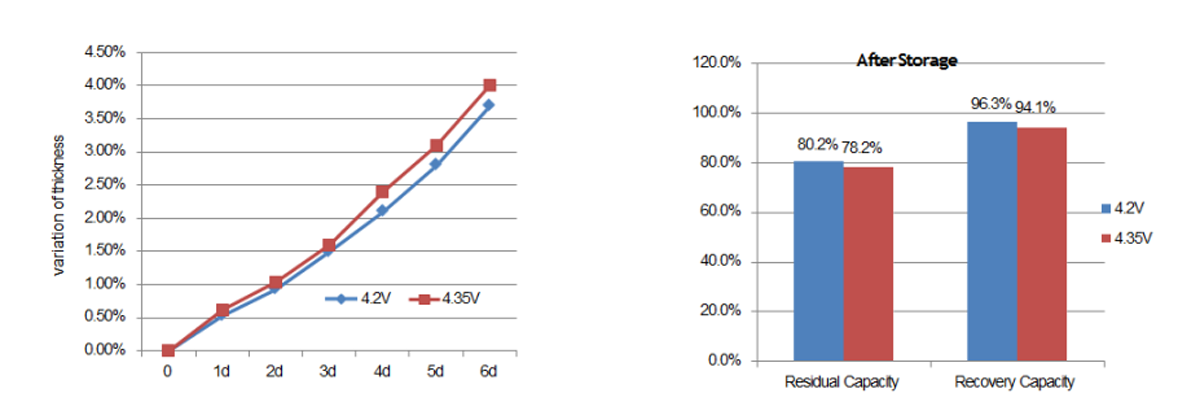

The cells were stored at 70 ℃ for 7 days, variation of thickness < 5%, recovery capacity > 90%.

High Temperature Storage Test Results

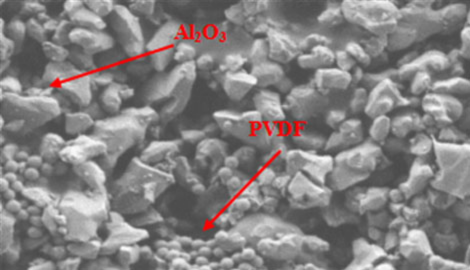

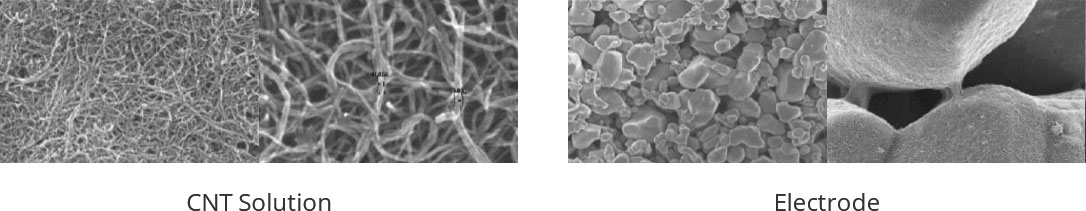

There is few agglomerate in CNT Solution.

In Electrode, CNT is well distributed on the surface of active materials.

CNT Solution and Distribution in Electrode

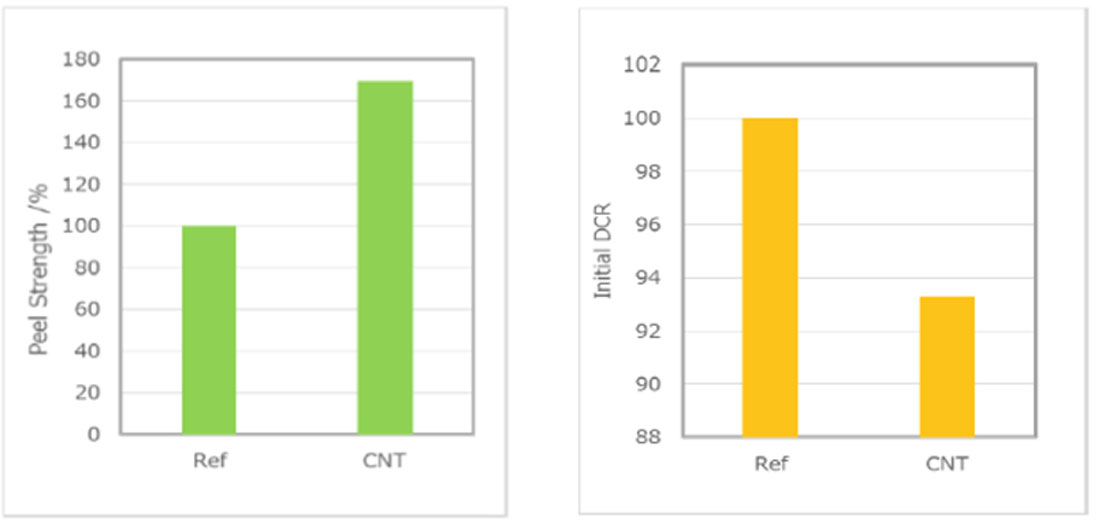

Better Peeling Strength and Smaller IR

We use cookies (and other similar technologies) to collect data to improve your shopping experience. By using our website, you're agreeing to the collection of data as described in our Privacy Policy.