The Many Factors Behind Drone Battery Performance

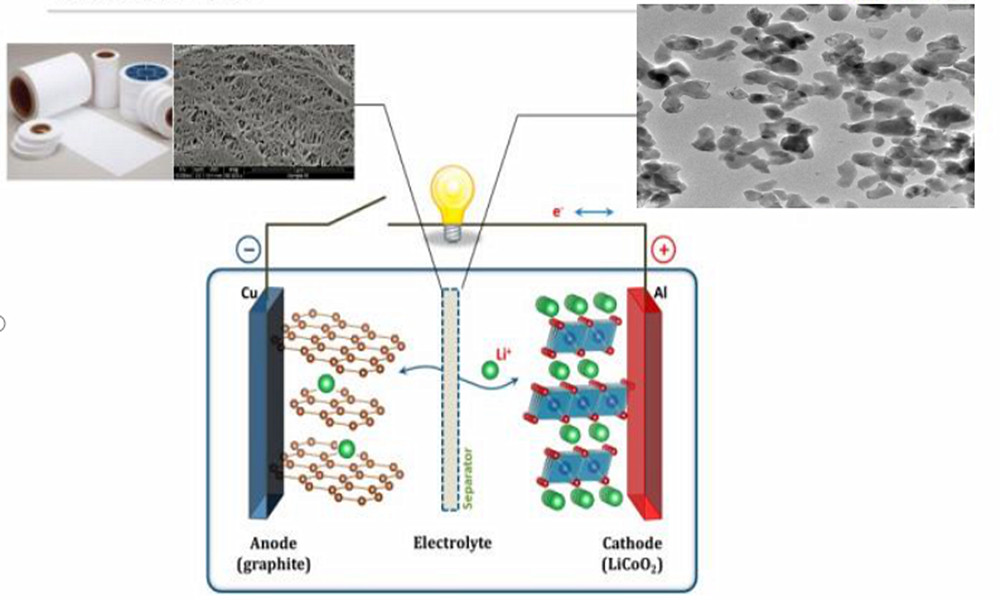

There are many advantages to utilizing Lithium Ion Polymer (LiPo) batteries for drones. Their large capacity, high energy density, high cycle life, and lack of memory effect are but a handful of reasons for why one would utilize these batteries as a power source. The technology for LiPo batteries is also developing rapidly year to year. The capacity, a critical indicator for performance, has attracted many researchers’ attention. Lithium Ion battery packs are especially moving towards the direction of larger capacities, faster charging, longer cycle life, and better safety.

Battery performance is dictated by cell configuration

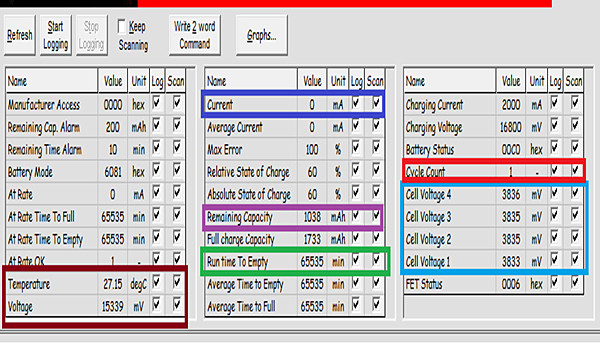

How is a battery’s performance measured specifically? There are many answers to this question that are based on the application of a battery. Long story short: The consistency of a battery is what matters. Users want to see consistency whether they use a battery for personal or industrial/commercial applications.

Battery consistency is largely dependent on the cells inside of a pack and how they’re matched in series or parallel. A good combination of cells improves not only cell utilization but also controls monomer consistency. This is the basis of achieving good discharge capacity and cycle stability. However, the cycle performance and available capacity of a battery can greatly decrease with the intensity of the dispersion degree of a.c. impedance of battery monomer capacity with poor configuration. Engineers have proposed a method to match cells based on the characteristics of a battery’s charge and discharge vectors. The closer the cells’ discharge or charge curves are, the higher the coefficients rate on energy displacement. We know that electricity travels in the path of least resistance. If one cell is drained or charged faster than its counterparts, a battery pack’s performance will slowly degrade. Unfortunately, the difficulty with this approach is the need to provide a standardized measurement for batteries. Due to the limitation of mechanical equipment, there must be differences between batteries produced in each batch. It is very difficult to obtain a set of characteristic vectors suitable for each batch of batteries.

GREPOW, which has more than 20 years of experience in battery manufacturing, uses a variety of methods to produce the best drone batteries. The methods include dynamic-characteristic matching, which is mainly based on the charge-discharge curve, and 32 other points which range from internal resistance accumulation rate to plating and many others. These different methods ultimately optimize the cell selection process when battery packs and modules are produced.

Proper Drone Battery Management

An appropriate charging system is important to the discharge capability of a battery. It is vital to understand that a battery’s capacity degrades when its SOC (State of charge) is consistently kept shallow. Users must also be aware that overcharging a battery affects its active chemical substances, which causes irreversible damage, such as a reduction in capacity, creation of heat spots, dendrite formation, plating, puffing, and more. It is thus necessary to select the appropriate charging rate, upper voltage limit, and constant voltage cut-off current. Users should also understand that modern-day LiPo chargers charge with two methods: voltage and amperage. When a uav battery is charged, the voltage from the charger is only slightly higher than the battery in order to allow the voltage to slowly be pulled up and the amperage to saturate the cells with energy. The best way to understand this idea is to think of a battery as a plastic bag. Voltage is equivalent to hands slowly lifting up the bag to create space and amperage the contents to fill the bag. Once the bag is fully enlarged, the voltage stops rising and the amperage is the only variable. Finally, the amperage slows down to top the bag off.

Engineers have proposed a variable-rate charging balancing solution. This solution adds additional energy to the low-energy, single battery without having to take out energy from a high-energy, single battery. This greatly simplifies the topology of the balancing circuit.

This is also the concept behind the BMS (Battery Management System) and its step charging, which allows a user to charge a battery at a higher voltage to speed up the charge without damaging the battery with too high amperage.

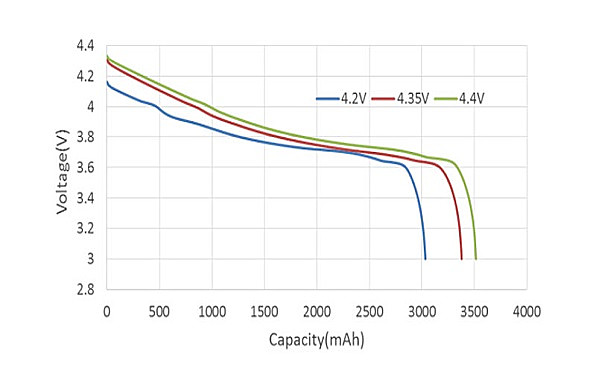

Drone Battery Discharge Rate

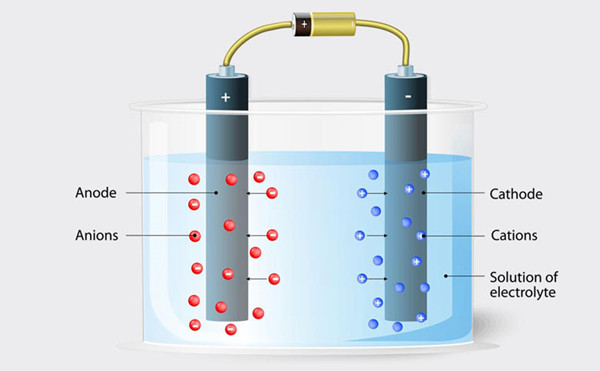

Discharge rate is an important indicator for batteries with high energy density. The available capacity of a battery decreases with the increase of the discharge current. The large rate discharge of a battery is a test for positive and negative electrode materials and electrolytes. The diffusion rate of lithium ions in electrolytes is the main factor that affects the discharge rate of a battery.

Therefore, different discharge rates lead to different discharge time and voltage platform ofa battery, which lead to a different discharge capacity. This is especially true for batteries in parallel. It is necessary to choose the right discharge ratio.

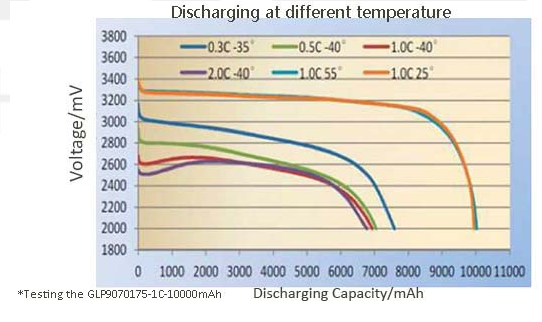

Temperature effects on Battery Performance

Low and high temperatures mainly affect electrolyte activity and properties of the electrode material inside a battery. At low temperatures, battery performance decreases: the electrolytes become viscous, thus slowing down the transfer of lithium ions. At the same time, all molecular activity in the battery coagulates and slows down, which results in an increased internal resistance. A higher internal resistance then causes the battery to utilize more power than a battery with a lower internal resistance.

When temperatures rise inside a battery, the lithium ions encounter less resistance and thus become more active. The positive effects of this include a reduced internal resistance, increased power output, and maximized capacity usage. In contrast, when temperatures rise too much, the stability of the internal resistance reduces, possible plating and drying of the electrolytes occur, the battery life shortens, etc. It is clear that both high and low temperatures affect the performance and service life of lipo drone batteries. Methods such as increasing the battery thermal management should be adopted to ensure that a battery works under a variety of temperatures. The best operating temperature for a battery is 25℃.

Related articles

Technology for future improvements in lithium ion drone battery

Keep an eye out for Grepow’s official blog, where we regularly post industry-related articles to keep you up-to-date on the battery industry.

Grepow: https://www.grepow.com/

Grepow Blog: https://www.grepow.com/blog.html

Related Articles

-

Tattu TA1000 Dual-Channel Smart Charger: The Versatile Charging Solution

2024-02-29 -

12V UPS Battery FAQs

2024-01-18 -

DC UPS vs AC UPS: What’s the Difference?

2024-01-11

Related products

-

Tattu 23000mAh 22.8V LiHv Pouch Cell UAV Battery

-

Tattu Plus 10000mAh 6S 22.2V Lipo Smart Drone Battery

-

Tattu Pro 14S 22000mAh 51.8V 25C Lipo Smart Drone Battery