How does an e-bike battery management system work?

Summary: Recently Edwin's e-bike battery broke down. Stopped working and took him on a quest to decipher how a Battery Management System (BMS) works. In this article, Edwin was shared what he learned from that journey. Source from Medium by Edwin Mol.

It took a bit long time to know that the BMS was the faulty component in the battery, but finding a replacement for it was more than just a quick search on Google and a click to buy the part I needed.

To explain how a BMS works let’s take a look at how a typical e-bike battery is constructed.

The basic building block is a 18650 Li-ion cell:

One cell does not contain enough energy to power an e-bike. One cell typically has a nominal voltage of 3.7 V and a capacity of around 3300 mAh.

A typical e-bike has a motor that runs at an operating voltage of 48 V and consumes up to 750 W. Therefore an e-bike battery contains lots of these cells combined together to supply the needed power the motor. Let’s look at how these cells are combined.

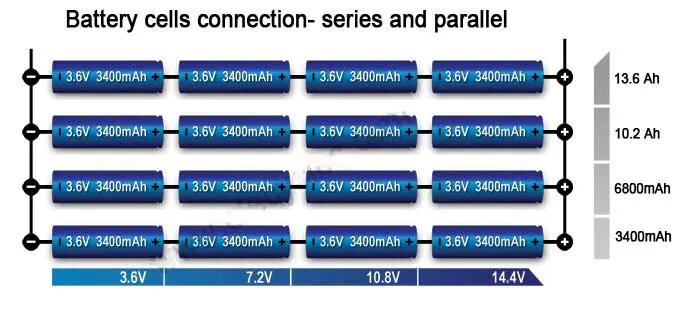

Basically there are two different ways cells can be combined. Either in series or in parallel.

Series and parallel connection

When cells are connected in series the voltage doubles, when combined in parallel the voltage remains the same. Therefore the only way to reach the needed voltage of 48 V or more is through series connection. Thirteen cells in series are needed to reach a voltage level of 48.1 V.

Apart from the voltage, the battery must be able to supply enough current to the motor and last long enough to be able to travel an acceptable mileage. Consider a motor of 48 V that consumes up to 750 W, the current needed for this is 15.6 A. This is much more than a single cell can supply sustainably, which is 3.3 Ah. In order to meet the current demand, we have to combine the cells in parallel. Connecting cells in parallel does not raise the voltage, but it does raise the current that the combination can supply. Therefore 5 cells in parallel can supply up to 16.5 A (5 * 3.3 A) which is enough to meet the demand.

A complete setup for a 48 V / 16.5 Ah battery pack, therefore, combines series and parallel connections. 13 series connections and 5 parallel connections. The complete pack contains consequently 65 cells.

18650 lithium-ion battery cell complete battery pack 48 V 16

Now that we know the layout of the cells. Let’s look at how a cell operates. A single cell has an operating range between 3.0 V and 4.2 V. This means that when we charge a cell, we can charge it up to a voltage or 4.2 V. Now the cell is fully charged. When the cell is discharged, it can be discharged until the voltage reaches the lower 3.0 V limit. Now the cell is fully discharged. It is critical to stay within these boundaries because overcharge or drainage of a cell can have dramatic consequences. Going beyond the maximum of 4.2 V can cause a cell to explode or burst. Going beneath the minimum of 3.0 V can lead to a dramatic reduction of a cell's life-cycle or damage the cell permanently.

Now, what happens when we combine cells that have different charge levels? Let's consider the parallel connection first. When connecting cells in parallel with different voltage levels, current will start to flow between the cells and they will balance themselves out until they all reach the same voltage level.

That is exactly what we need! We want all cells in a battery to operate at the same voltage level so we can control that all cells stay within the operation boundaries.

Now let's look at the series connection. What happens when combining cells at different charge levels?

Nothing happens! No current can flow between the two cells and they do not balance themselves. When we supply a load to this setup both cells will start to decrease their voltage level, but one of them will reach 3.0 V before the other. Now we have an undesirable situation. There is still capacity left in one cell, while the other is empty and must not be drained more to prevent damage. This situation is also true when charging. One of the two cells will reach the upper limit of 4.2 V first while the other is not fully charged yet.

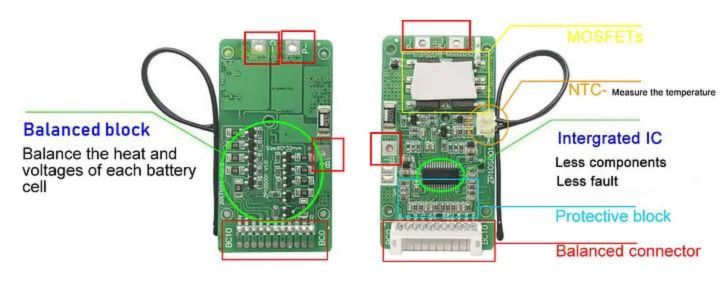

This is where a BMS steps in and helps to restore balance. A BMS protects your cells from over- or undercharge.

BMS in an E-bike battery

A BMS connects to all individual series connections, and can, therefore, monitor the voltage between each series connection. When they are diverging it will try to balance the voltage of all connections by charging or discharging the cells according to the need.

This protects your cells from wearing out to quickly or from being damaged. It is a small but invaluable piece of your e-bike battery.

The article is forwarded from Medium by Edwin Mol, original URL: Click Here

Learn more about batteries

Keep an eye out for Grepow’s official blog, where we regularly update industry-related articles to keep you up-to-date. Grepow website: https://www.grepow.com/

Grepow Blog: https://www.grepow.com/blog.html

Related Articles

-

New Racing Record | Red Bull Team Builds World's Fastest Drone to Chase F1

2024-03-02 -

Tattu TA1000 Dual-Channel Smart Charger: The Versatile Charging Solution

2024-02-29 -

What is a smart ring battery and the manufacturing process?

2024-02-02